Bezpečné řešení provádění šroubových spojů

Vytváření bezpečnějšího světa díky zaměření na integritu mechanických řešení, která jsou rozhodující pro náš způsob života

Náš příběhBezpečné řešení provádění šroubových spojů

Vytváření bezpečnějšího světa díky zaměření na integritu mechanických řešení, která jsou rozhodující pro náš způsob života

Náš příběhJak Vám můžeme pomoci?

Poskytujeme servis v odvětvích po celém světě

Ať už pracujete v jakémkoliv odvětví, společnost Nord-Lock Group nabízí technologie, které potřebujete k vyřešení svých komplexních problémů ohledně šroubových spojů. Máme několik desítek let zkušenosti s úspěšným řešením problémů specifických pro dané odvětví, a to po celém světě, proto se na nás můžete spolehnout i při řešení těch svých. Další informace o našich řešeních získáte výběrem požadovaného odvětví níže.

-

Stavitelství

Snadno použitelná řešení, která zaručí, že konstrukční spoje Vašich mostů a budov vydrží

Více informací -

Lesnictví a zemědělství

Již žádné opotřebení nosných ok otočných spojů – tak můžete zamezit prostojům a udržet své stroje na polích a v lesích v chodu

Více informací -

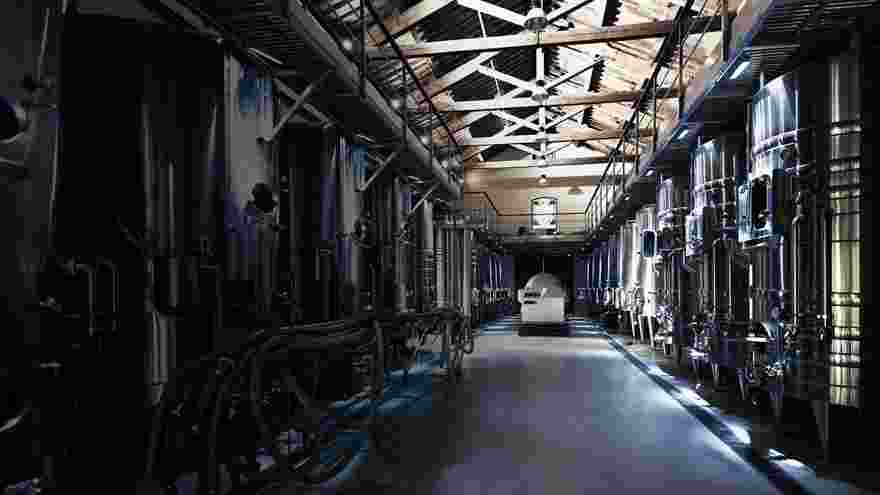

Průmyslová výroba a zpracování

Maximalizace výroby a minimalizace prostojů pomocí skutečně lícovaných šroubových spojů, které se nepohnou

Více informací -

Těžební průmysl

Technologie pro velká zatížení odolávající náročným podmínkám strojních zařízení v těžkých provozech

Více informací -

Těžba ropy a zemního plynu

Řešení jištění s rychlou instalací a výměnou, zajišťující Vaši bezpečnost i v těch nejdrsnějších podmínkách

Více informací -

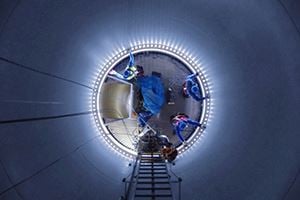

Výroba elektřiny

Utahování šroubů k podpoření nejmodernějších aplikací ve všech sektorech výroby elektřiny

Více informací -

Železnice

Šroubové spoje, které se nikdy nepovolí, bez ohledu na to, jak rychle jedete

Více informací -

Lodní stavitelství a námořní průmysl

Malé a účinné výrobky, které snesou zatížení Vašich velkých nákladních lodí a tankerů

Více informací -

Ocel, kovací a další lisy

Speciálně navržené ocelové stavební výrobky, které splňují přísné požadavky průmyslu

Více informací -

Doprava

Ať potřebujete řešení s nízkou hmotností pro vesmírnou družici, nebo řešení jištění kol těžkých vozidel, naše výrobky Vás dopraví z bodu A do bodu B

Více informací