Steel, Forging & Other Presses

Steel, Forging & Other Presses

To keep industrial heavyweights operational, careful attention must be paid to the bolted joints

Gold and silver may get all the attention, but few metals are more important than steel. Its social value is so great that steel production can even be seen as an indicator for economic growth. Steel skeletons are used in the construction of anything from bridges to cars, ships, airplanes as well as tools and appliances. It is the main material in renewable energy as well as the housing and construction sector.

Steel production has changed a lot since the industrial revolution, but it remains a demanding and intensive industry. In such harsh conditions, bolted joints need to hold despite constant exposure to corrosives, heavy vibrations and extreme temperatures. Any loosening will lead to unplanned maintenance and repairs, as well as costly delays in production.

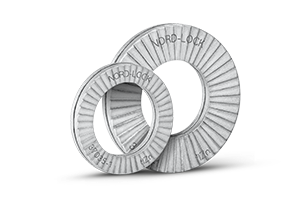

Nord-Lock Group products, such as our lock washers and Superbolt tensioners, can be applied quickly and easily, and they stay secure. The benefits include improved safety, increased productivity, reduced maintenance, and longer life-cycle. This is why they can be found in increasingly more steelworks bolting applications across the globe. Manufacturing operations all over the world rely on a variety of presses to create parts. To keep these industrial heavyweights operational, careful attention must be paid to the bolted joints.

Forging parts, molding objects, shaping pieces – large presses do these tasks everyday and perform them quickly and efficiently. As press designs become larger and larger, the demands on their bolted joints becomes more and more extreme. In many cases, the only viable bolting solution available on the market today, is the Superbolt multi-jackbolt tensioner (MJT).

Superbolt MJTs can tighten any size or diameter column or tie rod with simple tools and the cost of the MJTs can often be less than that of the large OEM replacements nuts. Superbolt tensioners have been fitted for column nuts in sizes up to 40” diameter threads (50,000 Ton forging press).

While forging presses are the most common application for Superbolt tensioners, they have also been incorporated into casting, molding, forming, injection molding, extrusion and industry specific presses such as plywood, pulp, rubber, and even large presses for industrial laundry water reclamation. There is no end to the applications for presses and fortunately the Nord-lock Group has safe and reliable bolting solutions for your specific needs!