Oferta standardowa

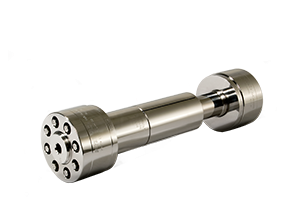

Mechaniczne śruby rozprężne EzFit można zaprojektować z wykorzystaniem nowoczesnej analizy elementów skończonych (FEA) dla dowolnego złącza ze śrubami o średnicy co najmniej 20 mm (3/4″).

Unikalne cechy i zalety hydraulicznych i mechanicznych tulejowych śrub rozprężnych można połączyć, aby jak najlepiej spełnić wymagania danego zastosowania.

|

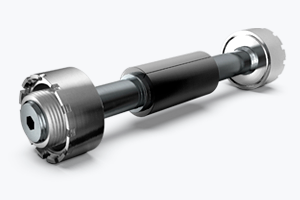

Typ A

|

|

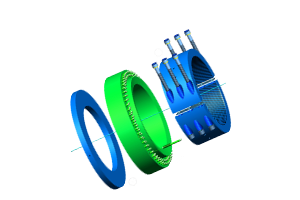

Typ B

|

|

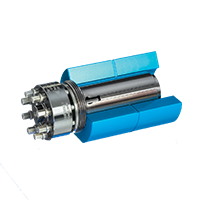

Typ C

|