Are costly leakages and unsafe bolting methods plaguing your heat exchanger operations? Discover a safer, more efficient solution with Superbolt multi-jackbolt tensioners (MJTs). Our white paper reveals how MJTs address common leakage and safety issues associated with critical heat exchanger flange bolting. Learn how MJTs can save you money, enhance safety, and streamline installation and removal processes. Download the white paper now to revolutionize your heat exchanger maintenance.

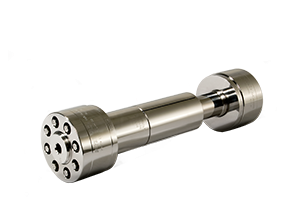

Solve Heat Exchanger Flange Issues with Superbolt® Multi-Jackbolt Tensioners

Download White Paper

Key Benefits of Superbolt MJTs

Cost Savings: Traditional bolting methods can incur substantial expenses due to equipment costs, downtime, and maintenance. MJTs offer a cost-effective alternative by reducing the need for hydraulic tensioning equipment and minimizing downtime associated with leakages and repairs. Our white paper includes detailed cost comparisons to showcase the long-term financial benefits of adopting MJTs for heat exchanger maintenance.

Enhanced Safety: Safety is paramount in any industrial setting. Traditional bolting methods, such as hot bolting and hydraulic wrenches, pose inherent risks to personnel due to high torque levels and heavy equipment. MJTs eliminate the need for cumbersome tools and minimize the risk of injuries associated with traditional bolting methods. Learn how MJTs can improve safety standards and create a safer work environment for your personnel.

Streamlined Installation and Removal: Traditional bolting methods often require extensive time and effort for installation and removal, leading to prolonged downtime and operational disruptions. MJTs offer a faster and more efficient alternative, allowing for quicker installation and removal processes. Discover how MJTs can streamline your maintenance procedures and maximize operational uptime.