How much thread engagement is needed in a tapped hole?

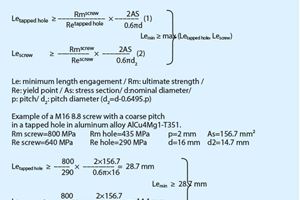

Is it possible to determine the minimum thread engagement in a tapped hole to avoid thread stripping?

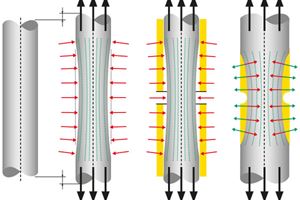

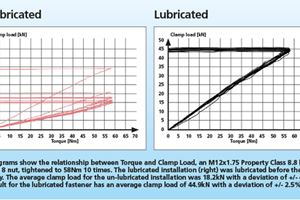

Every threaded joint must fulfill a simple engineering rule: any fastener failure must occur in the shank of the male fastener – bolt or stud. It implies that the shear strength of both internal and external threads overcomes the tensile strength of the bolt. Therefore the choice of the fasteners and the design of the assembly must avoid any possibility of thread stripping while making sure the weakest element in the joint is the bolt or the stud.

The shear resistance of any thread can be calculated by following E.M. Alexander’s method1, depending on four main parameters:

- The Young modulus E of the material

- The shear strength tm of the material

- The shear area of the thread, related to both the clearance between internal and external threads, and the effective thread engagement which is equal to the depth of tapped holes, minus the height of entry chamfers.

Nevertheless, tolerance can modify the previous indications: the wider the thread clearance, the smaller the thread stripping load. Calculation tools according to Alexander’s method can deliver accurate results.

1 Analysis and design of threaded assemblies, E.M. Alexander, 1977

Vil du læse flere af vores artikler?

Du kan få mere viden fra vores eksperter direkte in i din inboks.

Abbonere på vore nyhedsbrev nu!