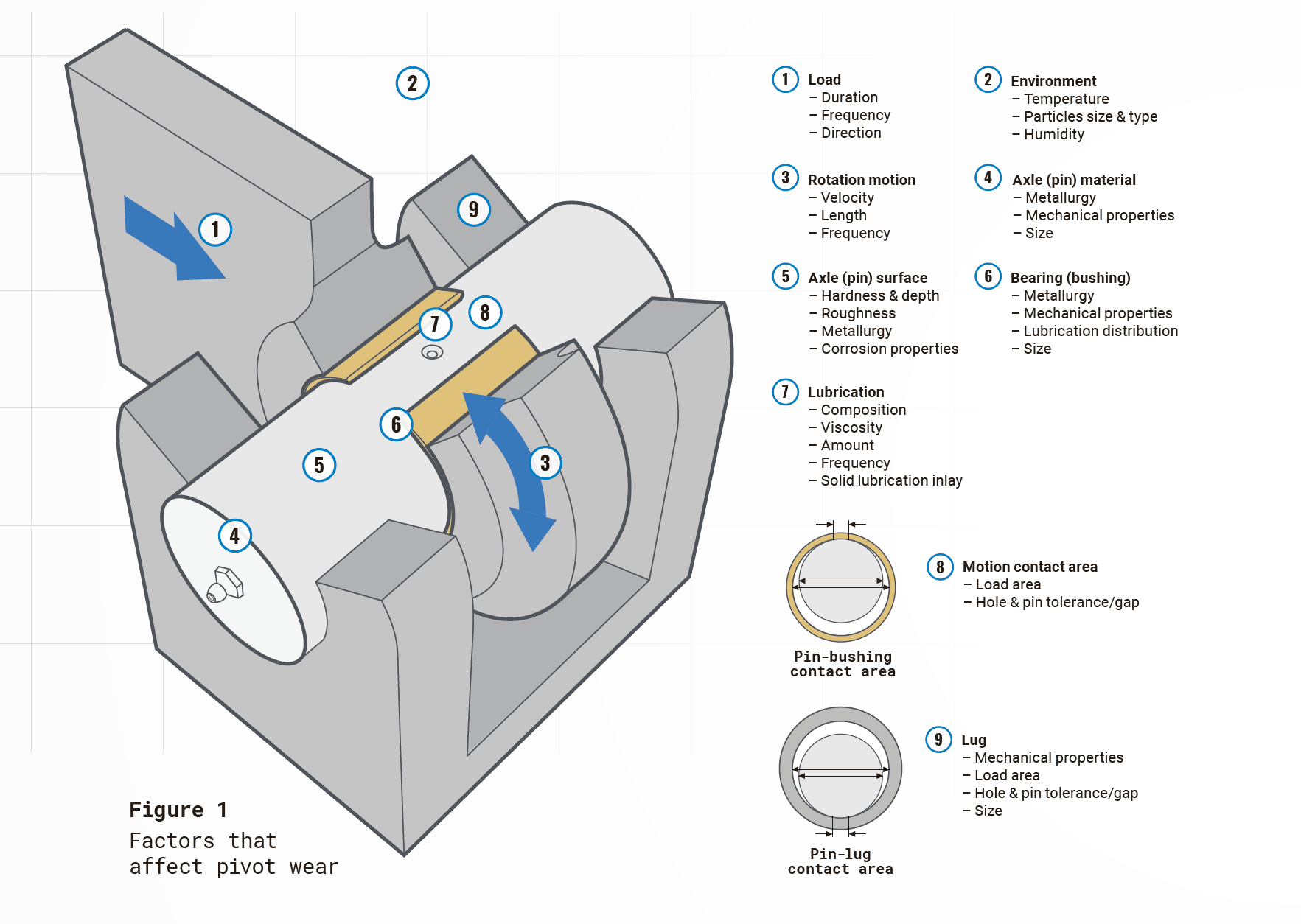

What affects pivot wear?

For a machine manufacturer there are many factors to consider to minimize pivot wear over time.

Pivot wear is the sum of bushing, axle and lug wear and there are many factors that influence it. While the machine manufacturers have multiple design options to minimize this wear, there are fewer options for the end-user, who would like to optimize uptime and service costs in an easy, cost efficient way. At this point, one can seldom do anything about the load, size of the pivot, velocity and frequency of the motion or the environment where the machine operates. What can be changed however is:

- If and how lubrication is used,

- Type of material, hardness and surface finish used in the axle and bushing,

- Fixation of the axle in the lugs.

As little bending as possible

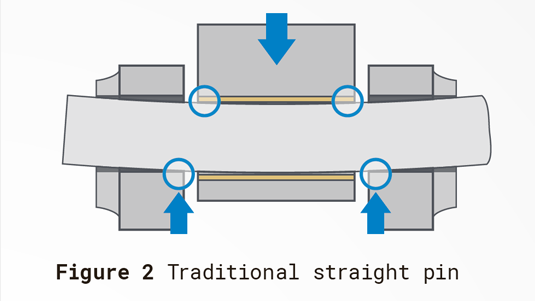

The factor that affects pivot wear the most is the load area in relation to the load/force, the surface pressure. If the pressure is high enough, there is no lubrication, material or hardness in the world that can prevent permanent damage to either the bushing, axle (pin) or lug. If the load remains the same but the area on which it acts is made smaller, the pressure increases. When loading a pivot, the axle (pin) will bend ever so slightly but enough to alter the contact area between the axle/bearing and the axle/lug. When there is low load on the pivot, the load is distributed over the full length of the bearing and lugs. When the axle bends as load increases, the areas will change and the pressure will increase (Figure 2).

How much the pressure changes depends not only on the load, length and diameter of the pin but also on the bushing’s mechanical properties. A more elastic bushing will help distribute the load to a certain extent after which it will either become plastic (permanent) deformation and/or force redistribution.

Benefits of axle fixation

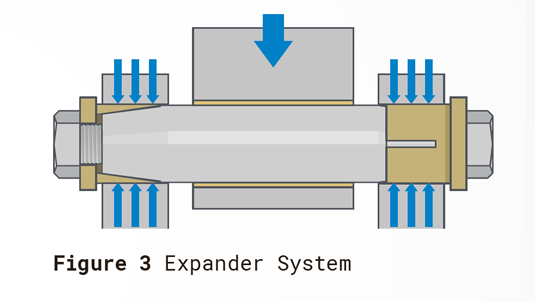

How much the axle (pin) bends is also dependent on whether it is fixed or loose at the ends. A traditional straight pin, which is only supported from the bottom of the lugs, is loose and will bend like a beam with simple supports. Expander System (Figure 3) is fixated in the lugs and will bend like a beam with fixed supports.

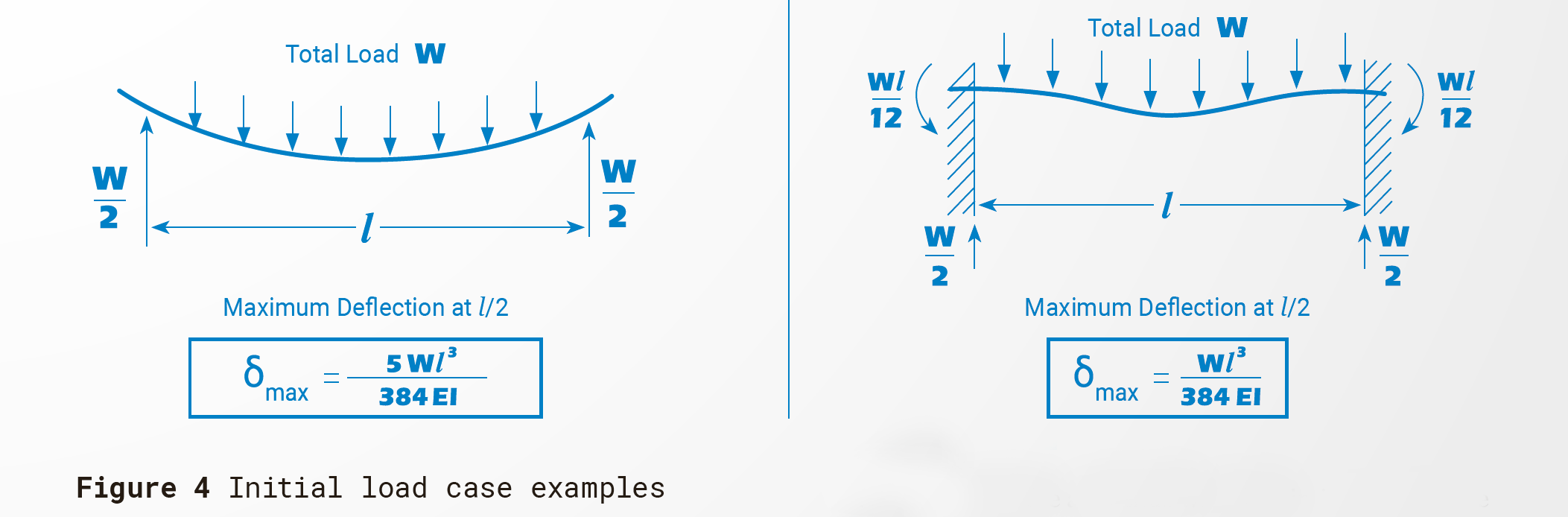

Depending on load case, a fixed supported axle will bend up to 5 times less than one with simple supports under the same load (Figure 4).

Approx. Traditional straight pin (Left figure)

Load case: Simple supports

The axle ends are only supported from the bottom due to the play needed during installation

Approx. Expander System (Right figure)

Load case: Fixed supports

The axle ends are fixed in the lugs by the expanding sleeves

The fixation of the axle ends will also limit the pin’s free radial movement to only be the clearance between bushing and axle. This helps to limit the acceleration of the mass and high impact forces on the bushing and pin. Expander System eliminates lug wear and reduces bushing/axle wear.

The fixation of the axle ends will also limit the pin’s free radial movement to only be the clearance between bushing and axle. This helps to limit the acceleration of the mass and high impact forces on the bushing and pin. Expander System eliminates lug wear and reduces bushing/axle wear.