Sea change

The Challenge

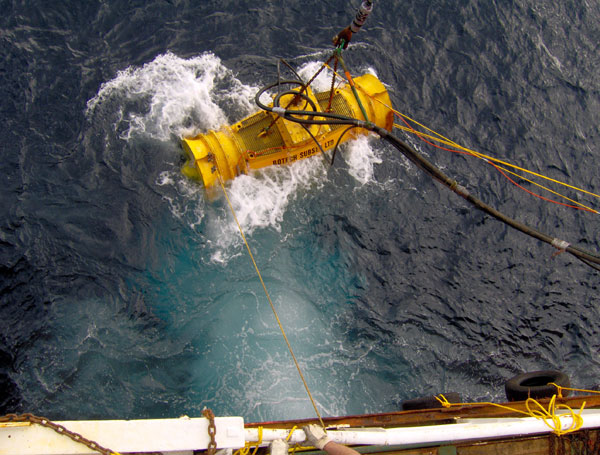

It is an all too familiar issue: bolts on heavy machinery vibrating loose during transport or operation. For Rotech Subsea, the world’s leading provider of mass flow excavation services, the problem could strike when their excavators were en route from its Aberdeen, Scotland, plant, or in action on the seabed at depths of up to 1,500 m, excavating the seabed using water at high-volume and low-pressure.

Their existing bolt securing solutions, such as lock tabs and spring washers, were coming loose due to vibrations or flexing, and although there was never an actual failure, Rotech’s engineers were concerned.

The Solution

Rotech Subsea turned to Nord-Lock, testing 200 pairs of washers on 1m-diameter bolted flange joints on an excavator bound for offshore work near Sakhalin, Russia.

“We put stainless steel washers on one side and zinc-coated washers on the other to see how they compared,” says Steve Aitken, senior research engineer at Rotech. “We have a kind of inbuilt salt sea spray test – the excavators sit and basically corrode on the back of a boat because of the environment. It sat there for a couple of months, then operated subsea, then spent another couple of months on the back of the boat before it was offloaded in Singapore.”

The Result

On inspection, Aitken found that not only were all the washers in perfect condition, but none had come loose. “Using Nord-Lock basically took all of our vibration worries away – they are like an insurance policy for us,” he says. “Something else we really appreciate is that you can actually feel that they are working when you loosen them off. It’s reassuring to tighten up a bolt to a certain torque and then loosen it off and make sure that the washer is working and everything is sitting well, and then tighten it back up again. I am now looking at using Nord-Lock washers on a wide range of R&D projects – not just subsea excavators.”