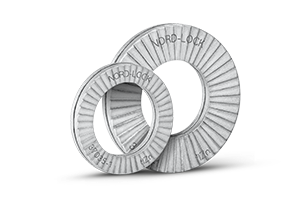

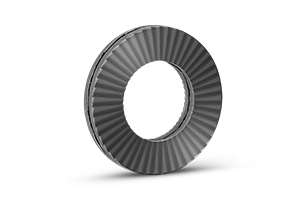

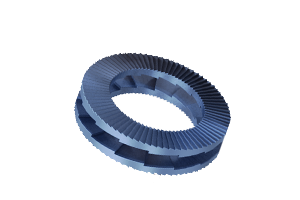

Nord-Lock originale skiver

Nord-Lock originale skiver

Nord-Lock Steel Washers |

||||

| Applications | General steel applications | |||

| Material standard | EN 1.7182 | |||

| Size range | M3-M130 #5 to 5" |

|||

| Corrosion resistance | Minimum 1,000 hours in salt spray test (according to ISO 9227) | |||

| Hardening | Through hardened | |||

| Washer hardness* | ≥ 465HV1 | |||

| Coating | Delta Protekt® KL100 zinc flake coating | |||

| Bolt grades | Up to 12.9 | |||

| Temperature range*** | -50°C to 200°C | |||

| Product designation | NL NLsp |

|||

| Laser marking type code | flZn | |||

* Washer hardness must be greater than the hardness of the mating surfaces in order to assure its mechanical function.

*** Temperature recommendations are based on information from the raw material supplier and testing. The locking function is not affected within the specified range.

Nord-Lock Stainless Steel Washers |

||||

| Applications | General stainless steel applications | |||

| Material standard | EN 1.4404 | |||

| Size range | M3-M80 #5 to 3 1/8" |

|||

| Corrosion resistance | PREN 27** | |||

| Hardening | Surface hardened | |||

| Washer hardness* | ≥ 520HV0,05 | |||

| Bolt grades | Up to A4-80 | |||

| Temperature range*** | -160°C to 500°C | |||

| Product designation | NLss NLspss |

|||

| Laser marking type code | SS | |||

* In order to assure the unique mechanical locking function of the Nord-Lock washers, the hardness of the mating surfaces must be lower than the hardness of the Nord-Lock washers.

** PREN (Pitting Resistance Equivalent Number) = %Cr + 3,3x%Mo + 16x%N. Figures in table valid for base material.

*** Temperature recommendations based on information from the raw material supplier and from tests. Locking function not affected within the specification.

Nord-Lock 254 SMO® Washers |

||||

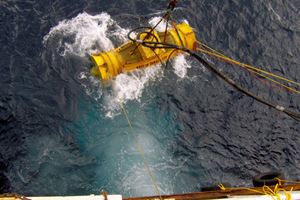

| Applications | Corrosive environment – chloride rich environments, offshore, pumps, heat exchangers, nuclear, food, medical, processing | |||

| Material standard | EN 1.4547 | |||

| Size range | M3-M39 #5 to 1 1/2" |

|||

| Corrosion resistance | PREN 45** | |||

| Hardening | Surface hardened | |||

| Washer hardness* | ≥ 600HV0,05 | |||

| Temperature range*** | -160°C to 500°C | |||

| Product designation | NLss-254 NLspss-254 |

|||

| Laser marking type code | 254 | |||

* In order to assure the unique mechanical locking function of the Nord-Lock washers, the hardness of the mating surfaces must be lower than the hardness of the Nord-Lock washers.

** PREN (Pitting Resistance Equivalent Number) = %Cr + 3,3x%Mo + 16x%N. Figures in table valid for base material.

*** Temperature recommendations based on information from the raw material supplier and from tests. Locking function not affected within the specification.

Nord-Lock Alloy C-276 Washers |

||||

| Applications | Acidic environment – chemical industry, evaporators, offshore, downhole tooling | |||

| Material standard | EN 2.4819 or equivalent | |||

| Size range | M4-M20 #8 to 1 1/2" |

|||

| Corrosion resistance | PREN 68** | |||

| Hardening | Surface hardened | |||

| Washer hardness* | ≥ 520HV0,05 | |||

| Temperature range*** | -160°C to 500°C | |||

| Product designation | NLss-276 NLspss-276 |

|||

| Laser marking type code | 276 | |||

* In order to assure the unique mechanical locking function of the Nord-Lock washers, the hardness of the mating surfaces must be lower than the hardness of the Nord-Lock washers.

** PREN (Pitting Resistance Equivalent Number) = %Cr + 3,3x%Mo + 16x%N. Figures in table valid for base material.

*** Temperature recommendations based on information from the raw material supplier and from tests. Locking function not affected within the specification.

Nord-Lock Alloy 718 Washers |

||||

| Applications | High temperatures – gas turbines, turbo charges, incinerators | |||

| Material standard | EN 2.4668 or equivalent | |||

| Size range | M4-M20 #5 to 1 1/2" |

|||

| Corrosion resistance | PREN 29** | |||

| Hardening | Surface hardened | |||

| Washer hardness* | ≥ 620HV0,05 | |||

| Temperature range*** | -160°C to 700°C | |||

| Product designation | NLss-718 NLspss-718 |

|||

| Laser marketing type code | 718 | |||

* In order to assure the unique mechanical locking function of the Nord-Lock washers, the hardness of the mating surfaces must be lower than the hardness of the Nord-Lock washers.

** PREN (Pitting Resistance Equivalent Number) = %Cr + 3,3x%Mo + 16x%N. Figures in table valid for base material.

*** Temperature recommendations based on information from the raw material supplier and from tests. Locking function not affected within the specification.

All types of Nord-Lock washers |

||||

| Material type | ||||

| Steel | Stainless steel (ss) |

254 SMO® | ALLOY C-276 |

ALLOY 718 |

| Applications | ||||

| General steel applications | General stainless steel applications | Corrosive environment – chloride rich environments, offshore, pumps, heat exchangers, nuclear, food, medical, processing | Acidic environment – chemical industry, evaporators, offshore, downhole tooling | High temperatures – gas turbines, turbo charges, incinerators |

| Material standard | ||||

| EN 1.7182 | EN 1.4404 | EN 1.4547 | EN 2.4819 or equivalent | EN 2.4668 or equivalent |

| Size range | ||||

|

M3-M130 #5 to 5" |

M3-M80 #5 to 3 1/8" |

M3-M39 #5 to 1 1/2" |

M4-M20 #8 to 1 1/2" |

M4-M20 #5 to 1 1/2" |

| Corrosion resistance | ||||

| Minimum 1,000 hours in salt spray test (according to ISO 9227) | PREN 27** | PREN 45** | PREN 68** | PREN 29** |

| Hardening | ||||

| Through hardened | Surface hardened | Surface hardened | Surface hardened | Surface hardened |

| Washer hardness* | ||||

| ≥ 465HV1 | ≥ 520HV0,05 | ≥ 600HV0,05 | ≥ 520HV0,05 | ≥ 620HV0,05 |

| Coating | ||||

| Delta Protekt® KL100 zinc flake coating | - | - | - | - |

| Bolt grades | ||||

| Up to 12.9 | Up to A4-80 | Up to A4-80 | Up to A4-80 | Up to A4-80 |

| Temperature range*** | ||||

| -50°C to 200°C | -160°C to 500°C | -160°C to 500°C | -160°C to 500°C | -160°C to 700°C |

| Product designation | ||||

| NL NLsp |

NLss NLspss |

NLss-254 NLspss-254 |

NLss-276 NLspss-276 |

NLss-718 NLspss-718 |

| Laser marking type code | ||||

| flZn | SS | 254 | 276 | 718 |

* In order to assure the unique mechanical locking function of the Nord-Lock washers, the hardness of the mating surfaces must be lower than the hardness of the Nord-Lock washers.

** PREN (Pitting Resistance Equivalent Number) = %Cr + 3,3x%Mo + 16x%N. Figures in table valid for base material.

*** Temperature recommendations based on information from the raw material supplier and from tests. Locking function not affected within the specification.

Udvælgelsesguide

| Appikations parameter | ||||

| Stål | Rustfrit stål SS | 254 SMO® | ALLOY C-276 |

ALLOY 718 |

| Stål type | ||||

| EN 1.7182 | EN 1.4404 | EN 1.4547 | EN 2.4819 eller lignende | EN 2.4668 eller lignende |

| Eksempler på applikationer | ||||

| Generelle stål applikationer | Generelle rustfri stål applikationer. Ikke klorholdige / sure miljøer | Generelle saltvands applikationer, pumper, klorholdige applikationer, varmevekslere, kernekraft, afsaltning, fødevare- og medicinal udstyr | Generelle sure miljøre, proces- og kemisk industri, fordampere, offshore ”down hole” værktøj | Applikationer men høje temperature, gas turbine, turboladere,forbrændingsanlæg |

| Findes til bolt størrelse | ||||

|

M3 til M130 #5 til 5" |

M3 til M80 #5 til 3 1/8" |

M3 til M39 #5 til 1 1/2" |

M3 til M39 Tilgængelig ved henvendelse #5 til 1 1/2" Tilgængelig ved henvendelse |

M3 til M39 Tilgængelig ved henvendelse #5 til 1 1/2" Tilgængelig ved henvendelse |

| Skive typer | ||||

|

Standard yder diameter (NL3 til NL130) Stor yder diameter (NL3,5sp til NL36sp) |

Standard yder diameter (NL3ss til NL80ss) Stor yder diameter (NL3,5spss til NL30spss) |

Standard yder diameter (NL3ss-254 til NL39ss-254) Stor yder diameter (NL3,5spss-254 til NL27spss-254) |

Standard yder diameter (NL3ss-276 til NL39ss-276) Stor yder diameter (NL3,5spss-276 til NL27spss-276) |

Standard yder diameter (NL3ss-718 til NL39ss-718) Stor yder diameter (NL3,5spss-718 til NL27spss-718) |

| Behandling / Overfladebehandling | ||||

| Delta Protekt® base coat (KL100) og top coat (VH302GZ) | Overflade hærdet | Overflade hærdet | Overflade hærdet | Overflade hærdet |

| Skive hårdhed* | ||||

| ≥ 465HV1 | ≥ 520HV0,05 | ≥ 600HV0,05 | ≥ 520HV0,05 | ≥ 620HV0,05 |

| Korrosionsbestandighed | ||||

| Minimum 1,000 timer i salttåge test (iflg. ISO9227) | PREN 27** | PREN 45** | PREN 68** | PREN 29** |

| Bolt kvaliteter | ||||

| Op til 12.9 | Op til A4-80 | |||

| Temperatur område*** | ||||

| -50°C til 200°C | -160°C til 500°C | -160°C til 500°C | -160°C til 500°C | -160°C til 700°C |

* For at være sikker på af få Nord-Lock´s unikke låsefunktion skal hårdheden på den overflade man spænder imod være blødere end hårdheden på Nord-Lock skiverne (Se ovenstående tabel).

** PREN (Pitting Restistance Equivalent Number) =%Cr + 3,3X%Mo+16X%N. Tallene I tabellen gælder for grundmaterialet.

*** Temperatur anbefalinger er baseret på information fra råvareleverandøren. Låsefunktionen bliver ikke påvirket inden for det specificerede område.

Skive hårdhed

For at være sikker på af få Nord-Lock´s unikke låsefunktion skal hårdheden på den overflade man spænder imod være blødere end hårdheden på Nord-Lock skiverne.

| Skive type | Området | Zinc Flake overflade-behandlet flZnnc – 600 | Ikke overflade-behandlet |

| Stål skiver (Gennemhærdet) | NL3 - NL42 NL45 - NL130 |

≥ 465 HV1 ≥ 465 HV1 |

|

| Rustfrie skiver (Overflade hærdet) | NL3ss - NL80ss | ≥ 520 HV0.05 | |

| SMO 254® skiver | NL3ss-254 - NL80ss-254 | ≥ 600 HV0.05 |

Hårdheds konverterings tabel

| Vickers HV |

Brinell HB |

Rockwell HRC |

Rockwell HRA |

8.8 bolt |

10.9 bolt |

12.9 bolt |

| 300 | 285 | 29,8 | 65,5 | | | ||

| 310 | 295 | 31,0 | 65,8 | | | ||

| 320 | 304 | 32,2 | 66,4 | | | 320 HV | |

| 330 | 314 | 33,3 | 67,0 | | | | | |

| 335 | 319 | 33,9 | 67,3 | 335 HV | | | |

| 340 | 325 | 34,4 | 67,6 | | | ||

| 350 | 333 | 35,5 | 68,1 | | | ||

| 360 | 342 | 36,6 | 68,7 | | | ||

| 370 | 352 | 37,7 | 69,2 | | | ||

| 380 | 361 | 38,8 | 69,8 | 380 HV | ||

| 385 | 366 | 39,3 | 70,1 | 385 HV | ||

| 390 | 371 | 39,8 | 70,3 | | | ||

| 400 | 380 | 40,8 | 70,8 | | | ||

| 410 | 390 | 41,8 | 71,4 | | | ||

| 420 | 399 | 42,7 | 71,8 | | | ||

| 430 | 409 | 43,6 | 72,3 | | | ||

| 435 | 414 | 44,1 | 72,5 | 435 HV | ||

| 440 | 418 | 44,5 | 72,8 | |||

| 460 | 437 | 46,1 | 73,6 | |||

| 480 | (456) | 47,7 | 74,5 | |||

| 500 | (475) | 49,1 | 75,3 | |||

| 520 | (494) | 50,5 | 76,1 | |||

| 540 | (513) | 51,7 | 76,7 |