Which washer material should I choose?

Nord-Lock washers come in five different materials. How do I know which one to use in my application?

It is correct that Nord-Lock washers are available in five different materials. Two of the materials are offered as standard and work in a wide range of applications. The most common material is a through-hardened steel washer coated with a zinc flake coating. We also offer our washers in stainless steel in A4 quality. The stainless steel washers are surface hardened to safely secure all grades of stainless steel fasteners. For customers with applications in extreme environments, fasteners in special materials may be needed.

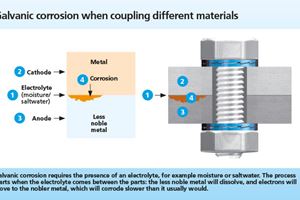

Which material to choose depends on the environment, see below table. If you need further assistance with choosing the right material for your application, you are always welcome to contact our material expert.

| Material | Application area | Industry examples |

| Steel, EN 1.71825, Zinc flake coating | All purpose | Machine screws |

| A4, AISI 316L, EN 1.4404 | Corrosive environment | Most stainless steel applications |

| SMO 254®, AISI S31254, EN 1.4547 | Salt water, Chlorides | Food/Subsea/Pump applications |

| Inconel 718, ASTM N07718, EN 2.4667 | High temperature | Gast/Steam turbines, Heat exhausts, Turbo compressors |

| Hastelloy/Inconel C-276, ASTM N10276, EN 2.4819 | Severe corrosive environments | Acidic natural gas |