Combating Corrosion Effectively

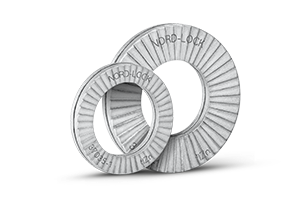

Tested for at least 1,000 hours in the Neutral Salt Spray Test, Nord-Lock steel washer promises the highest salt spray resistance on the market.

Corrosion is a growing concern across industries and the requirements are increasing in environments where accelerating factors such as humidity, heat and air pollution are combined.

1,000 hours is the minimum amount of time Nord-Lock steel washers with zinc flake coating by Delta Protekt® can withstand corrosion in a salt spray test. The regular quality testing that is done as part of ensuring high-quality standards, clearly shows that the washers consistently endure even longer hours.

| Nord-Lock steel washer corrosion resistance | Environment category | Corrosion risk | Examples of environment |

| 25 years* | C4 | High | Industrial areas and coastal areas with moderate salinity |

| 15 years* | C5 | Very high | Industrial areas with high humidity and aggressive atmosphere and coastal areas with high salinity |

*According to ISO 12944-6:2018, 1,000 hours in a salt spray chamber correspond to approximately 25 years in C4 environment or approximately 15 years in C5 environment.

We have perfected our coating process so that we can promise 1,000 hours.

"If you look at the results of the salt spray tests that we do every week, the washers on average do endure over twice as long in the salt spray chamber before any signs of corrosion occur," says Anders Knutsson, Coating and Corrosion Expert at Nord-Lock Group.

Neutral Salt Spray Test

The neutral salt spray test, (NSST according to ISO 9227), is one of the most established corrosion testing methods in the industry. It was designed to test the resistance of materials and surface coatings against corrosion, by exposing them to high concentrations of salt over a specific period of time.

The test itself is conducted in a chamber with a controlled atmosphere and level of corrosivity. The corrosive environment in the chamber can be altered depending on the type of material being tested. The suitability of the material or surface coating is judged by the length of time it takes for corrosion to appear.