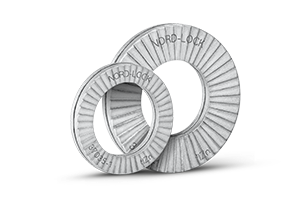

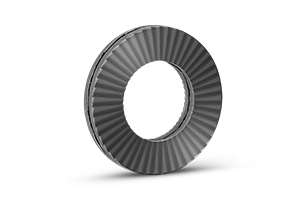

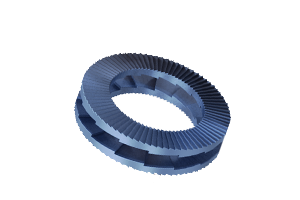

Steel Construction Washers

Steel Construction Washers

Joint Guide

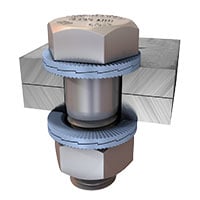

Nord-Lock SC-washers can be used with HV / HR bolts and nuts.

|

Through-holes |

|

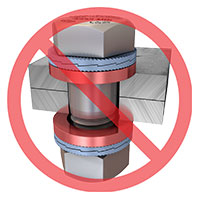

Designs where Nord-Lock SC-washers are not recommended:

|

Torque Guidelines

Note that the torque guidelines below only apply to HV bolts with NLSC washers.

|

Washer

|

Reduced preload force |

Modified |

|

Modified combined |

Securing [Nm] |

| NL12SC | 45 | 130 | 100 | 80 | |

| NL16SC | 90 | 330 | 250 | 200 | |

| NL20SC | 145 | 660 | 490 | 360 | |

| NL22SC | 170 | 850 | 640 | 520 | |

| NL24SC | 200 | 1100 | 825 | 640 | |

| NL27SC | 260 | 1600 | 1220 | 1000 | |

| NL30SC | 315 | 2150 | 1650 | 1320 | |

| NL36SC | 460 | 3750 | 2800 | 2240 | |

*Tightening conditions are specified in ETA-13/0246 for HV bolts, grade 10.9.

Required angle of further rotation

| Clamp length | angle | part tum |

| t < 2d | 45° | 1/8 |

| 2d ≤ t < 6d | 60° | 1/6 |

| 6d ≤ t ≤ 10d | 90° | 1/4 |

| 10d < t | No recommendations | |

| Tightening angles when using the combined method varies depending on the clamp length, (t), in relation to bolt diameter, (d). | ||