Amusement park safety: Leaving nothing to chance

When it comes to amusement park attractions, safety is absolutely crucial. However, maintenance can both be expensive and time-consuming. But there is a solution for worn-out axles and bearings that can solve the problem. Permanently.

Some people love them and can’t get enough. Others, not so much. When it comes to thrills — or outright fright — amusement park attractions cover much ground.

Whether you want to take a free fall from 80 meters height, go at high speeds upside down then into a hairpin curve, or generally expose yourself to crazy G forces, you’ve got it. But let’s face it. It would be taking it too far if you couldn’t depend on safety.

Most attractions move much mass at high speed, so there are tremendous forces at play. It can put extreme loads on the, mostly, steel structures and the carriages. Safety and reliability are paramount to avoid incidents or accidents.

Strict demands throughout the value chain

Even though the number of accidents remain relatively low in Europe, the European Committee for Standardization, CEN, introduced a new European standard, EN 13814 “Safety of amusement rides and amusement devices”, in May 2019. It covers everything from the design of an attraction to operation and maintenance to monitoring and inspections.

The standard puts heavy demands on manufacturers and on the companies that operate amusement parks. According to Peter Andersson:

“Safety is a fundamental part of our business and covers the visitors as well as our staff. We never compromise on that.”

He is the Ride Maintenance Manager at the Gröna Lund amusement park in central Stockholm and at Parks and Resorts Scandinavia, the group that owns and operates Gröna Lund as well as some of Sweden’s most popular theme parks.

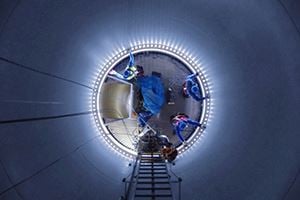

Parks and Resorts’ local maintenance departments perform meticulous daily controls of both rails and carriages, looking for any wear or damage. Yearly, the carriages are dismantled, and all parts are X-rayed. According to licensing authority rules, in-depth checks are carried out every five years, where attractions are dismantled into small pieces.

Often enough to change washers

As in all engineering, loosening bolted joints are a safety hazard. For example, the Gröna Lund attraction Eclipse is made from 910 tons of steel and concrete and involves 80,000 bolts. That is a lot of potential problems.

“If we detect any bolt loosening, we often perform root cause analysis. Generally, it is enough to switch to Nord-Lock washers,” says Andersson who first learned about Nord-Lock wedge-locking washers back in 1998, when they were used to secure the rails on one attraction after visual inspection.

“When I saw how well that solution turned out, there was no going back,” he says.

“Since then, if we find loose bolts, we immediately order Nord-Lock washers.” Many attraction manufacturers specify Nord-Lock washers already at the design stage. They generally find use in large bolted joints, in applications such as the rails and steel structures, but also for moving parts in wagon brakes.

A solution that saves time and money

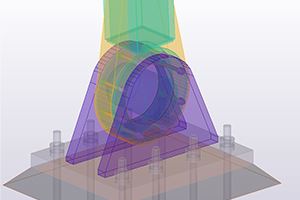

Apart from using Nord-Lock washers, Parks and Resorts is also partial to the Expander System to counter lug wear. This has saved a lot of money and minimized downtime compared to traditional repairs, such as line boring. But it has also significantly prolonged attraction lifespans, which translates into serious savings, given that a new big-sized attraction can cost upwards of 900,000 euros.

Andersson first learned about the Expander System back in the late 1990s too: “We had tried various reparation solutions, but the feeling was always, ‘there must be something better’. Then we found the Expander System.”

Since then it has been used on numerous attractions at Gröna Lund, including Octopussy. In 2009, Expander System was installed on all arms of the attraction, which has worked flawlessly since then. Another exciting attraction is the Flying Carpet – the oldest at Gröna Lund.

“It has a historical value, and it is difficult to find a replacement,” Andersson says. “About eight years ago, we noticed wear on a critical stay. Attending to this would traditionally have meant doing new calculations and finally a complete inspection, which would probably have meant that the attraction would have been put out of commission.” Expander System replaced the worn-out axles and bolts, and the Flying Carpet is still used safely.

The use is spreading

The use of the Expander System has spread within Parks and Resorts. When the maintenance department at the Kolmården wildlife and amusement park contacted Andersson about installing the Expander System on their attractions, he was happy to recommend it.

The wheel bogie suspensions on attraction wagons are usually a weak spot as they are under the most significant strain. Due to wear and tear on the axles, chassis hole tolerances get enlarged, sometimes in just a couple of years.

Fredrik Johansson, a mechanic at Kolmården, says: “If you’ve been at it for 30 years like me, you know that if something is loose, you’ve got a problem. And given our high safety standards, we don’t put together any makeshift solutions. If it costs a bit more, then that’s okay.”

Saving money in the long-term

At first glance, the Expander System may seem expensive but in a life cycle perspective, you can save money, Johansson explains. “Comparing the purchasing price of the Expander System to dismantling an entire attraction and sending parts away for line boring, the latter is both more costly and time-consuming.”

As a mechanic, Johansson appreciates how easy the Expander System is to install. There is no line boring or welding involved, you can perform it at the site, directly in the worn mountings.

"It’s a brilliant solution, we have used it for a season now,and it just works. Problem solved".

Customer: Parks and Resorts Scandinavia AB

Number of visitors: Approximately 3 million each year

Applications: Several, including securing rails, brakes and steel structures

Business: Owns and operates four of Sweden's most popular theme parks, Skara sommarland, Gröna Lund, Kolmården and Furuvik

The solution: Expander system and Nord-Lock wedge locking washers