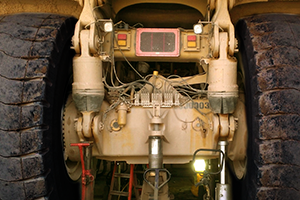

A typical mining venture spends 35 to 50 percent of its annual operating budget on equipment maintenance and repairs. Friction and wear process during extraction, materials handling and material processing results in need for costly and time-consuming repairs. For 40 years Expander System have developed, designed and supplied solutions to some of the world's biggest mining equipment manufacturers; Caterpillar, Komatsu, Liebherr, Volvo and more.

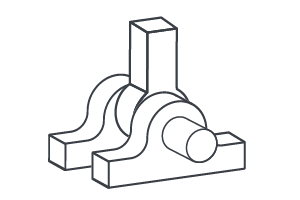

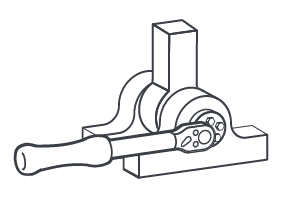

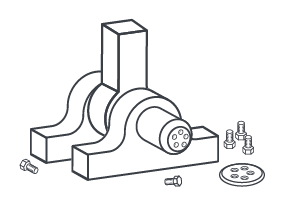

- When the fasteners are tightened, the washers press the slotted expansion sleeves up the tapered ends of the pin.

- The sleeves expand to conform with wear patterns and lock the system in place.

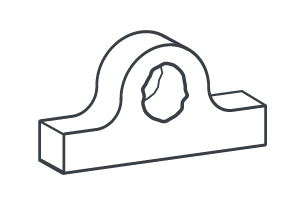

- Expander System fits into the existing mount without expensive welding and line boring.

- Once re-torqued according to instructions, the system locks from both sides for significantly greater stability.

- Removal and reinstallation are easy, and the system is reusable indefinitely.