Benefits of Using Bolted Joints in the Industrial Sector

Industrial processes are becoming increasingly complex. Manufacturers have to integrate new, high-tech materials and functionality into increasingly lighter, stronger, cheaper and more reliable products.

But one element has remained constant, the role of the bolted connection to keep components securely fastened. Manufacturers need fastening solutions that are widely available, standardized and easy to assemble. So, what exactly are the benefits (and challenges) of using bolts?

Download Nord-Lock Group’s white paper – ‘Safe Bolted Joint Design: An Introduction to Why Bolted Joints Fail and How to Make Them Safer’

Industries now anticipate product life cycles early on in the development phase, with departments such as R&D, quality, aftermarket, operations and sales each defining their requirements. The way components are connected is of major concern as it impacts every step of how a product is used.

Assembly lines are still mainly operated by humans, which makes them error prone. Therefore, easy processes are encouraged to reduce mistakes and increase product quality and safety. Multiple advantages have ensured that bolted joints are one of the most popular methods to connect components in the industrial sector today.

Bolted joints are easy to use

The bolted connection is an appealing method due to its ease of use. It combines a screw/stud with a threaded counterpart such as a nut or tapped hole and only requires a simple torque wrench to operate. This differentiates it from other technologies such as:

- Bonding: relies on the operator’s judgement to determine quality and correct application.

- Riveting: this assembly requires press tools that makes the process more complex.

- Welding: requires a certified welder, advanced tooling and failure can remain undetected.

Bolted joints are flexible

A bolted joint is not a permanent assembly, it can be easily removed and reused using the same tools with which it was assembled. This is very helpful for maintenance, simple checks or replacement of parts. It is also useful when the product is at the end of its life cycle as parts made of different materials can be separated, sorted and recycled effectively.

Bolts come in many sizes and materials

Bolts are available in a range of sizes and materials depending on the demand of the application. They are commonly made of steel, which provides strong mechanical characteristics that are usually greater than the capacities of the assembled parts.

Bolts can clamp different materials together

Bolts can be used to join parts made of materials that are different than the bolt itself, such as plastics and composites. No special arrangement or design is required to make this assembly compatible.

Bolts can secure thick parts

The thickness of the assembled parts can be as large as they need to be to fit the manufacturer’s needs. The thickness and the hole size can be produced with large tolerances. This usually implies economical and regular well-known machining processes.

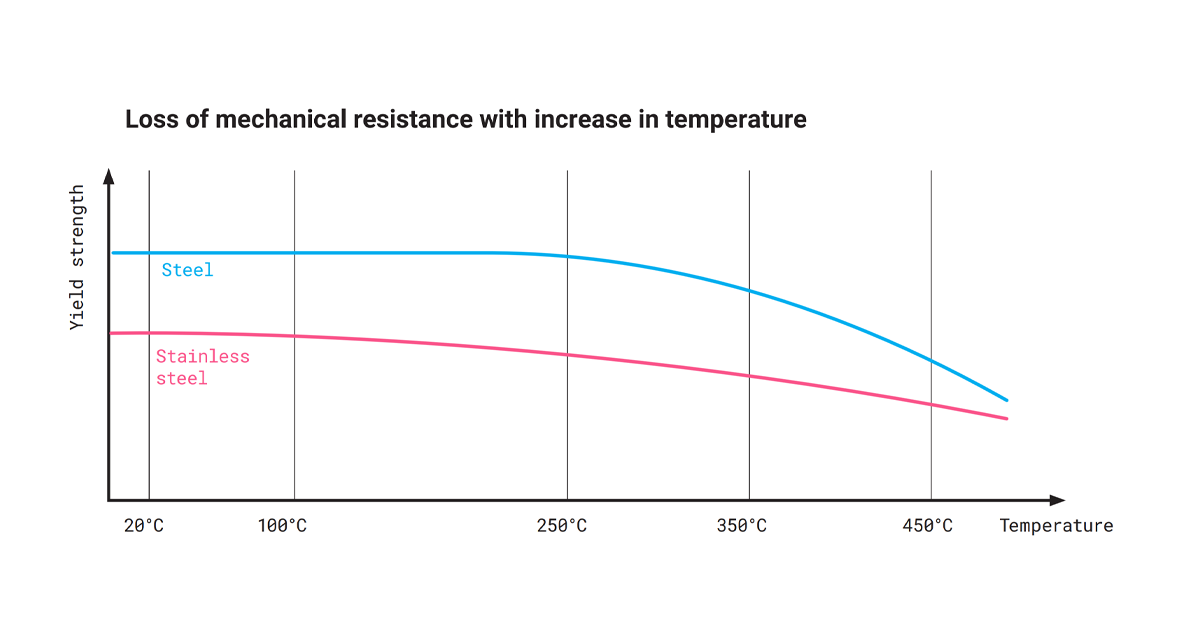

Bolts can operate at a wide temperature range

Normalized steel bolts can sustain temperatures between -50°C and 200°C and for wider demands, stainless steel bolts can function between the ranges of -160°C and 500°C. Special designs using materials able to sustain high temperatures and alloys capable of functioning in an acidic environment can bring the connection to the right level of performance.

Thanks to the above advantages, the bolted joint is widely used in the industrial sector as a practical and cost-effective solution.

Bolt manufacturers and distributors have become well established and are able to provide affordable products that answer increasingly complex demands.

This article is taken from Nord-Lock Group’s white paper, ‘Safe Bolted Joint Design: An Introduction to Why Bolted Joints Fail and How to Make Them Safer’. Download your copy for free using the form below and get more information on:

- Benefits of using bolted joints in the industrial sector

- Disadvantages of using bolted joints

- Consequences of bolted joint failure

- Best practices to increase bolted joint safety