What are the thermal effects on preloaded bolted joints?

Negative effects on bolted joints

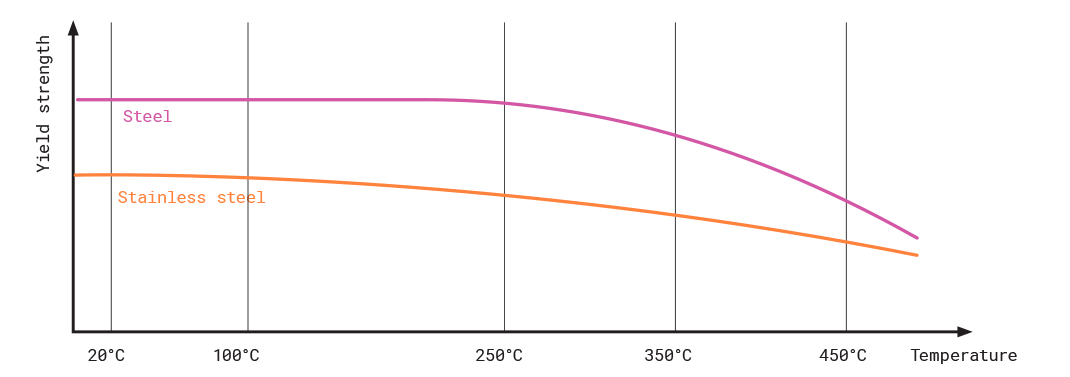

Service temperatures above 250°C activate creep and relaxation phenomena in alloyed and construction steels. Hence, despite bolts being preloaded in their elastic state at the service temperature, a portion of the preload is relaxed in proportion to the reduction of yield strength of the steel fastener.

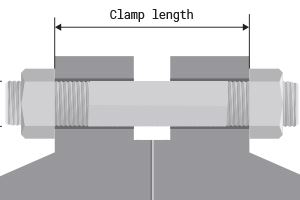

Due to temperature variations, parts and fasteners expand or contract with various amplitudes depending on the rate of temperature change, the mass, and size of parts, conductivity of metals, and the coefficient of expansion of each individual material. These differences in relative expansions or retractions between materials and parts generate variations in preload in the joint. Often, the maximum amplitude of preload variation occurs during transient states.

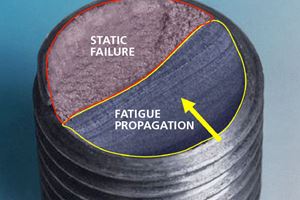

Thermal cycling can also generate thermally-induced fatigue since not all areas expand simultaneously with the same amplitude. The boundaries between “hotter” and “colder” areas undergo extra stress, which can lead to local fatigue of the material. However, when the temperature is stable and uniform in all parts, it is recommended to use materials with homogeneous coefficients of expansion to minimize the variation in clamp load or take that preload modification into account for the joint design.

It’s possible to overcome the above challenges by following state-of-the-art design codes, material selection, and joint-calculation guidelines by:

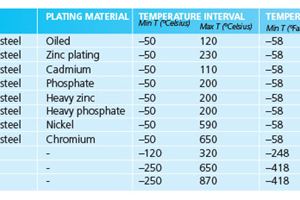

- Verifying adequate material selection regarding the behavior of mechanical characteristics at service temperature to avoid dramatic metallurgic changes such as precipitates, aging or heat treatment (i.e. tempering or annealing).

- Checking that no excessive stress will occur due to load variation, caused by service loads and by differential relative thermal expansion (or contraction) during thermal cyclings.

- Anticipating how much preload will be lost via creep and relaxation phenomena.

Nord-Lock Group experience and solutions

Nord-Lock Group products, from wedge-locking washers to multi-jackbolt tensioners, are often used in extreme environments.

When guiding customers through product selection, product design, and joint design phases, we follow state-of-the-art guidelines to provide safe and durable components for bolted joints. We review material selection to account for service temperatures and risks of corrosion and creep.

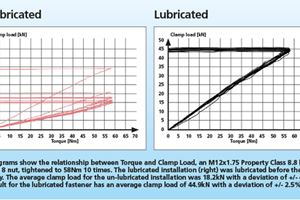

Next, we review the preload range, from tightening at ambient temperature to the residual (or extra) load in service. When necessary, coating, lubricant, and dry films are applied. We also assist users in their design phase to avoid any risk of failure regarding the joint itself.

Like this article and want more?

Get engineering and bolting insights delivered straight to your inbox. Subscribe to our insights newsletter now!