The Experts: The story behind the phenomenon

What is “the Virgin Bolt Phenomenon”?

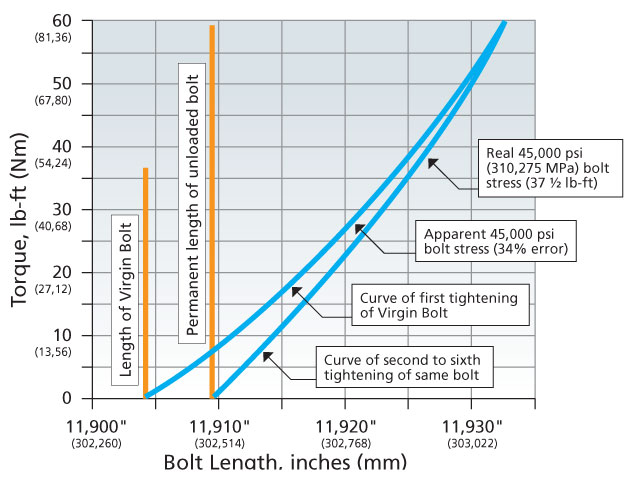

’Virgin Bolt Phenomenon’ was a phrase coined by Rolf Steinbock during early research on Superbolt tensioners. To establish preload values, corresponding test studs were stretched by torquing a Superbolt tensioner, and the overall length was measured pre- and post-test (using Hooke’s Law to calculate load). Inconsistencies in testing were occurring that resulted in a strange curve in the charted data that could not be explained. When re-measuring the studs after the test load had been released, a curious phenomenon was observed whereby the test studs did not always return to their original overall length, causing a significant error (34% in one test).

Curiously, this only happened on the very first test. Following this, the studs always returned to their newly established base length. The apparent ‘permanent stretch’ was not caused by material yielding as tests were performed below yield values. Further testing indicated that this is an issue with pre-heat treated material being machined down to a stud. It was not observed for post-heat treated bolts. It was suggested that heat treating causes the outside of a bar to harden quickly, placing the core under severe compression and pushing the grains together. Peeling off the outer layer for manufacturing purposes relieves this pressure. An externally applied tensile load on the finished stud effectively re-orients the grains (like un-kinking a chain).

Curiously, this only happened on the very first test. Following this, the studs always returned to their newly established base length. The apparent ‘permanent stretch’ was not caused by material yielding as tests were performed below yield values. Further testing indicated that this is an issue with pre-heat treated material being machined down to a stud. It was not observed for post-heat treated bolts. It was suggested that heat treating causes the outside of a bar to harden quickly, placing the core under severe compression and pushing the grains together. Peeling off the outer layer for manufacturing purposes relieves this pressure. An externally applied tensile load on the finished stud effectively re-orients the grains (like un-kinking a chain).

When critical stretch measurements are required on “virgin” machined studs for test or field service, it is imperative to stretch a stud once and re-establish a new base length to ensure correct values. The ‘Virgin Bolt Phenomenon’ is not commonly known but is an important variable to take into account when evaluating stretch measurements properly’.

Do you have a question about bolt securing?

Put the Nord-Lock experts to the test.

Email your questions about bolt securing to

experts@nord-lock.com