The Experts: Getting the most out of fasteners

Can I re-use bolts?

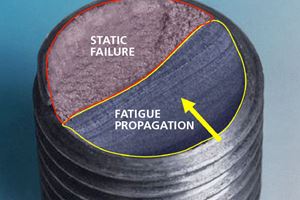

Before you re-use bolts, you should always consider the security level of the assembly and economic factors. Operators often lack important information, such as if the assembly working load or working temperature have been exceeded. As fatigue cracks are difficult to detect, the use of a new bolt (screw, nut and washer) is often recommended for security and legal reasons.

You can re-use bolts:

- If re-usability has been specified by the assembly designer

- If a bolt failure does not endanger its environment, for example the full structure, the safety of operators or others. The assembly is not critical.

- For temporary/emergency use. A periodic control is recommended.

Before re-using threaded fasteners, always make a visual inspection of the head and/or nut for signs of damage or corrosion. Check that the coating on coated fasteners is not damaged or worn away. Ensure that there is no permanent deformation of the threads by running a new nut over the thread engagement length of the screw. Inspect the fastener shank for signs of reduction in diameter “waisting”, indicating that the yield strength of the fastener has been exceeded.

Before re-using threaded fasteners, always make a visual inspection of the head and/or nut for signs of damage or corrosion. Check that the coating on coated fasteners is not damaged or worn away. Ensure that there is no permanent deformation of the threads by running a new nut over the thread engagement length of the screw. Inspect the fastener shank for signs of reduction in diameter “waisting”, indicating that the yield strength of the fastener has been exceeded.

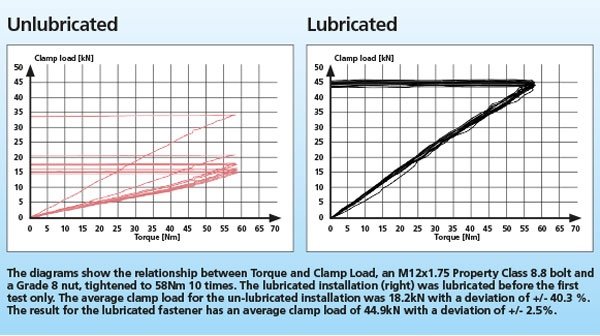

Clean the internal and external threads and all contact areas. Using the same or similar tightening condition as on the initial installation – such as torque level, tool class or lubricant type – ensures that the same clamp load is achieved.

If the fastener is initially assembled un-lubricated, the surfaces of the bearing area and threads will degrade under pressure when untightening, increasing the coefficient of friction between these surfaces. Tightening on re-use to the initial torque value will result in a reduced clamp load, because of the higher coefficient of friction of these surfaces. Subsequent re-use will progressively reduce the clamp load and then be consistent at a low preload and a lot of problems could take place, such as fatigue, vibration or joint separation.

Do you have a question about bolt securing?

Put the Nord-Lock experts to the test.

Email your questions about bolt securing to

experts@nord-lock.com