Cumulative global hydropower installations are expected to reach 1,691 GW by 2025. Wind energy now covers 11.6% of the EU’s electricity demand. The energy sector faces significant challenges in meeting the demands of the world’s growing population. Whether you are extracting deep sea oil or constructing towering wind turbines, many of the challenges are the same. How do you ensure structural integrity, uphold safety standards and make your project as reliable and robust as possible?

The answer lies in innovation, investing in R&D and forming long-term partnerships with manufacturers who share your vision. Whatever tomorrow might have in store for the global energy sector, that collaborative approach is what will turn concepts into workable projects and overcome technical difficulties with the smartest of solutions.

Creating Tension and Maintaining It

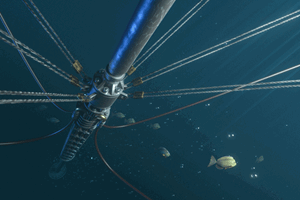

As engineers develop ever larger power stations, taller turbines and longer blades, these problems are accentuated. Bolt fatigue, relaxation and corrosion is a huge concern for project engineers. It is also critical that accurate and reliable tools are used to ensure bolts are at the right tension or torque.

In 2015, a V112 wind turbine collapsed at the Lemnhult wind farm in Sweden due to the failure in the bolted flange between tower sections one and two. First reports suggested the quality of the bolts was to blame, yet further investigations concluded the fault lay with incorrect bolt pre-tensioning procedures.

Hydraulic bolt tensioning tools are now widely used across the renewables sector for accurate and easy tightening of bolts to the correct pre-loads. How can this method be far safer and more reliable than conventional tightening methods?

Find out more in the white paper.