At Nord-Lock Group, we are committed to delivering exceptional support to the nuclear industry through our innovative engineered solutions, unwavering dedication to safety, and best-in-class performance!

1. Single bolt tensioner

Boltight® hydraulic single bolt tensioners are high quality tools especially useful for critical bolted connections. We have as well our auto return tensioners, the TSR+ range, bringing reliability and time saving during critical nuclear operations. Custom products can be designed and manufactured to the client’s exact specifications with plenty of possible options.

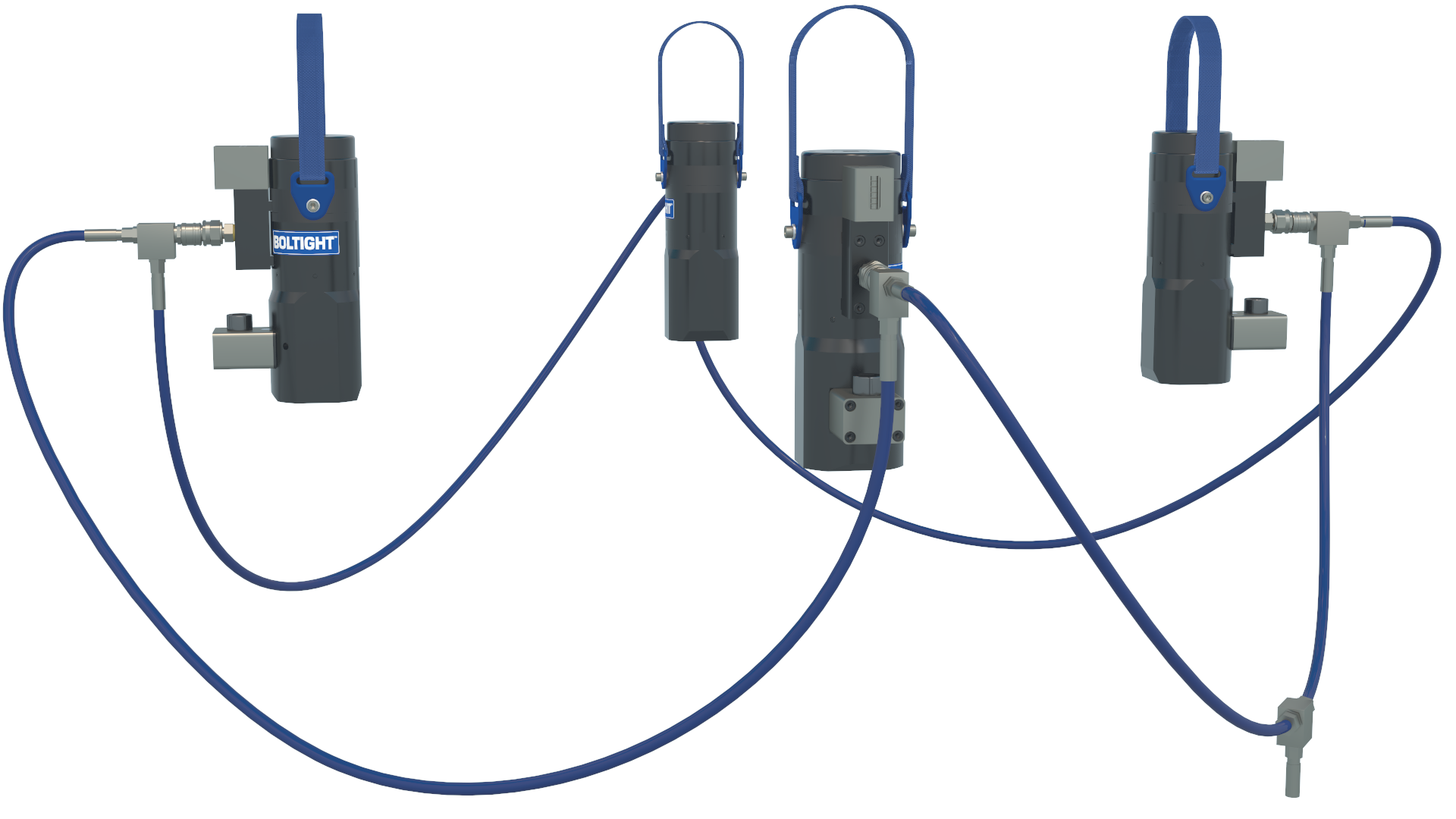

2. Multi-stud tensioners

Boltight Multi-stud tensioners (MST) allow simultaneous tightening of all bolts in a joint, speeding up installation time and reducing the time personnel need to be in a highly radioactive environment. MST’s can be supplied in complete ring or segmented depending on application.

3. Hydraulic nut

Boltight Hydraulic nuts are a permanent replacement for standard nuts and remain on the application after tensioning.

4. Multi-Jackbolt Tensioner

Superbolt® Multi-Jackbolt Tensioners (MJTs) deliver high preload in a compact format. Thanks to their unique design, they allow to break down the load among multiple small jackbolts. The main benefit is that it can be installed by a single operator with a simple hand torque wrench.

5. Wedge-locking washers

Nord-lock® wedge-locking washers are a reliable alternative to tab washers, a commonly used untightening method in the nuclear industry. Nord-lock® washers are safer, quicker, and easier for the operator to install/uninstall but also more reliable when it comes to dynamic applications. They can be used on valve (including on earthquake-qualified equipment K1, K2, K3), pumps, and pipe flanges but also on cable trays, safety systems and filters (IRWST, drum screens). It can of course also be used on handling and lifting equipment and as any standard industrial applications in the machinery room.