The Experts: Why do Superbolt multi-jackbolt tensioners prevent loss of preload?

Superbolts have been used in numerous demanding bolting applications with extreme working loads and high vibrations. What mechanical principle of Superbolts prevent loss of preload?

Preventing loss of preload is certainly a major advantage of a Superbolt. However, it stems from Superbolt’s ability to attain the proper preload in the first place. This is because, for a properly designed bolted joint, achieving the proper preload (clamping load) over the working load (separating force) is what keeps fasteners tight.

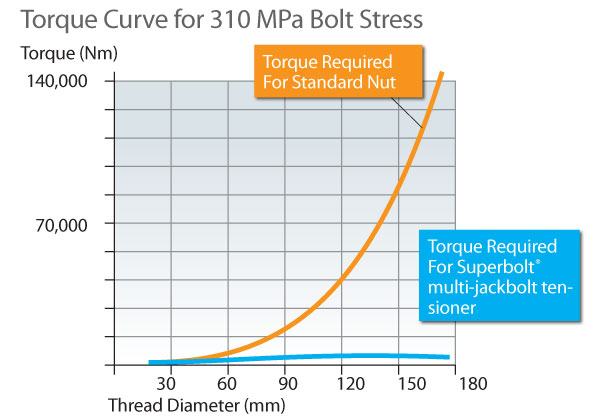

However, in the majority of cases, achieving proper preload is extremely difficult, especially when tightening conventional hex nuts. This is because as the bolt diameter increases, the torque required to reach a certain bolt stress increases by a power of three. Therefore it is very difficult to easily tighten hex nuts that are over one inch.

The torque required to tighten Superbolt tensioners, on the other hand, are kept low since the large preload is spread over many smaller bolts known as jackbolts, which need only to be torqued with simple hand tools. Also, with controlled lubrication and minimal frictional losses, Superbolt reaches high preloads with superb accuracy and repeatability.

The torque required to tighten Superbolt tensioners, on the other hand, are kept low since the large preload is spread over many smaller bolts known as jackbolts, which need only to be torqued with simple hand tools. Also, with controlled lubrication and minimal frictional losses, Superbolt reaches high preloads with superb accuracy and repeatability.

Integral to the design, Superbolt adds desirable elasticity to the bolted joint, which helps maintain preload, especially in thermal or dynamic applications. Testing shows that Superbolt tensioners maintain the preload even when subjected to a million cycles of high dynamic load at a level of 98% of the applied preload. Many other tests, including fatigue and vibration tests, have been performed. For further details, test reports are available.

Do you have a question about bolt securing?

Put the Nord-Lock experts to the test.

Email your questions about bolt securing to

experts@nord-lock.com