Why does torque vary when tightening and untightening?

Why is the untightening torque lower than the tightening torque when tightening a bolt or nut?

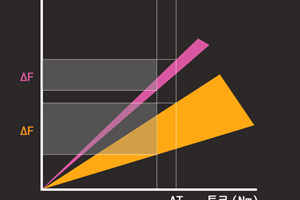

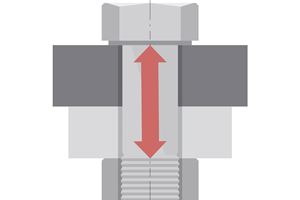

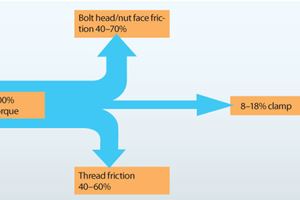

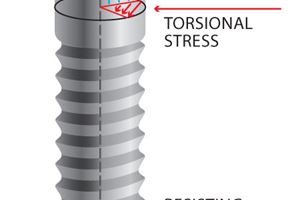

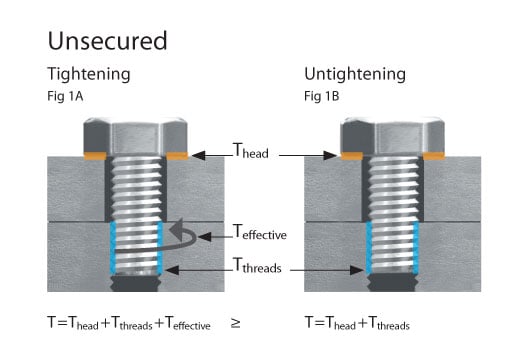

When tightening a bolt or nut, the applied torque must overcome the thread friction, the friction under the bolt head or nut and the inclined plane of the thread, to obtain a bolt preload (see Fig. 1A).

While untightening, provided that the assembly remains in the same condition, the applied torque only has to overcome frictional forces. As a result, untightening a fastener requires a lower torque (see Fig. 1B).

There are some exceptions to this rule. Since friction conditions vary, higher torque can be required to untighten a fastener. Corrosion, seizing, or surface roughness can considerably increase friction and subsequently the untightening torque.

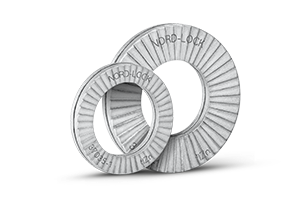

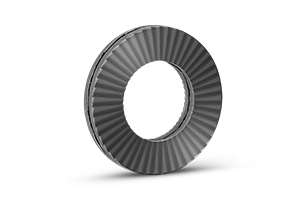

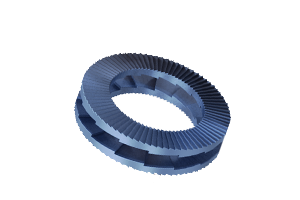

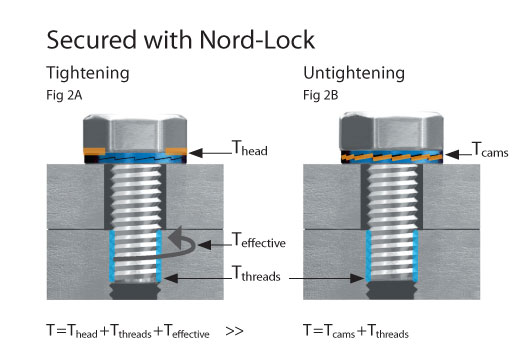

With Nord-Lock washers, the difference between the tightening and untightening torque is even more significant. During tightening, sliding occurs between the bolt head or nut and the serrated surface of the upper Nord-Lock washer (see Fig 2A).

However, during untightening, sliding occurs between the cam faces of the washers, where friction is significantly lower (see Fig 2B).

This is a valuable feature of Nord-Lock washers, as a low untightening torque facilitates maintenance and thereby reduces downtime.

Like this article and want more?

Get engineering and bolting insights delivered straight to your inbox. Subscribe to our insights newsletter now!