Comparison of common bolt tightening methods

Proper preloading of a bolted connection is a difficult task. Therefore, several different tightening methods were developed – each with their specific advantages and disadvantages. So, different methods are preferred in different industries or for certain applications.

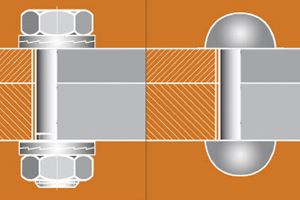

Generally, tightening methods can be categorized according to the principle of how the preload is generated. There are 2 basic principles:

- Rotational tightening (torque controlled, angle controlled, yield controlled), where the tensioner is rotated to directly produce the preload.

- Tensioning (hydraulic, thermal, mechanical), where the bolt is stretched without rotating the tensioner, typically by means of an external power supply.

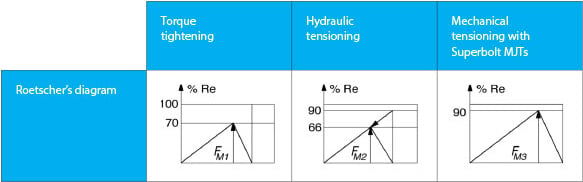

For large boltings, especially for large sizes above M39 or 1.5”, the three tightening methods shown below are predominant. This comparison is based solely on the indisputable physics behind these methods and illustrated with the help of Roetscher’s diagram.

| Torque tightening | Hydraulic tensioning | Mechanical tensioning with Superbolt multi-jackbolt tensioners | |

| Consider an ideal bolted connection where the thickness of the clamped parts is 5x the diameter of the thread. The typical design criteria is that the tensile stress in the bolt may not exceed 90% of the yield strength. | If this connection is torque tightened, the bolt can only be used to 70% of its yield strength (Re) because approximately 30% is lost due to torsional stresses induced by the tightening torque. | With hydraulic tensioning the bolt is stretched by means of a powerful hydraulic tool to the permissible 90% of the bolt’s yield strength (Re). The nut is spun down and snugged up to the clamped members to remove all backlash. When the hydraulic pressure is relieved, the bolt springs back again to tension the nut. Thereby approximately one-third of the load produced by the hydraulic tool is lost. Thus, the bolt can only be used to around 66% of its yield strength (Re). For longer tie rods this value may increase up to 80%. | With Superbolt MJTs, small jackbolts are tightened without rotating the tensioner on the main thread. The preload produced by these jackbolts acts directly on the bolt. There is no detrimental torsional stress or springing back of the bolt. The bolt may be utilized to the full 90% of the yield strength (Re). |

Like this article and want more?

Get engineering and bolting insights delivered straight to your inbox. Subscribe to our insights newsletter now!