No loosening in steel structures

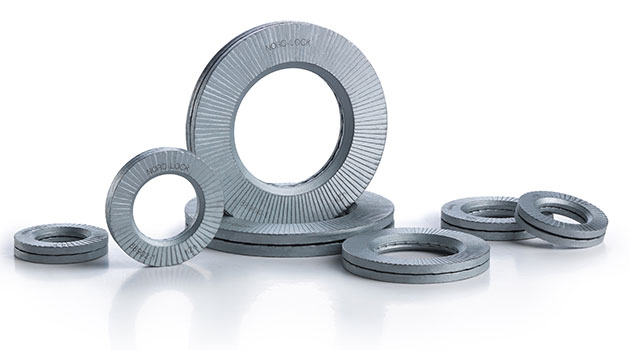

Issues with loosening bolts in steel constructions are solved with Nord-Lock’s new SC-washers.

Until recently there was no satisfactory way to secure HV bolts (according to EN 14399) used in structural steelwork such as bridges or ceiling-mounted cranes. When bolts came lose due to vibration or dynamic loads, there was no solution apart from the time-consuming and expensive process of retightening.

But now Nord-Lock has introduced a new range of washers specially designed to fit the HV bolting systems used for steel construction in Europe. The SC-washers (steel construction washers) have received certification in Germany from the DIBt (German Institute for Civil Engineering) and European certification is pending.

“When vibrations occur in these structures, the bolts fitted with the original washers from HV sets loosen and it is not possible to maintain the clamp load,” says Frank Hüssing, Nord-Lock sales engineer in Germany. “The industry has long been searching for a solution, so we came up with a specific new product to fit the existing bolting system and the very specific geometries that are demanded.”

In Germany the commonly used HV sets consist of one bolt, two washers with special chamfering, and one lubricated nut. All parts are zinc coated. Nord-Lock’s SC-washers can be exchanged for the original washers as they have the same inner and outer diameter. In order to fit the special geometry of the bolt head, the Nord-Lock washers have a particular chamfer at the inner diameter. The pair of Nord-Lock’s SC-washers feature chamfers on both sides to eliminate the risk of incorrect assembly.

Nord-Lock started marketing the product directly to customers in Germany this year. As our SC-washers are used mainly in conjunction with HV sets, they will be available through distributors as well as through direct sales.

Hüssing says that feedback from customers so far has been very positive. “Whenever bolts in these steel constructions start to loosen the company has to send a technician to retighten them. This is costly and means the bolt security is no longer guaranteed. So customers really appreciate having a bolt securing system in which these problems do not occur, even under dynamic loads and vibrations.”

Sales to customers in the rest of Europe will start once European certification has been received. “However, this will never be a standard product, but a highly specialised product that is desperately needed in this specific industry,” says Hüssing.