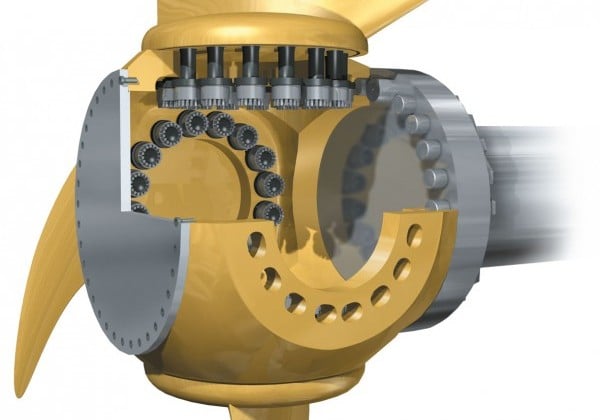

Adjustable bolted propeller

Ship propeller - bolting of propeller blades

The Challenge

Large ships are increasingly being equipped with higher propulsive power. This trend is generating a need for larger propellers. Such propellers are typically of monobloc design, i.e. constructed from one casting. They are difficult to machine and their high weight and bulk make handling and transportation a costly enterprise.

Large ships are increasingly being equipped with higher propulsive power. This trend is generating a need for larger propellers. Such propellers are typically of monobloc design, i.e. constructed from one casting. They are difficult to machine and their high weight and bulk make handling and transportation a costly enterprise.

The Solution

Rolls Royce had the idea for a bolted propeller using Superbolt already in 1992. Superbolt High Strength Tensioners give additional elasticity to a bolted connection through the unique design with highly loadable jackbolts, especially on short bolts. The blades can be tightened using light hand tools from inside the hub. The task can be performed underwater.

Installation:

Hundreds, approved by Germanischer Lloyd, e.g. 400 pcs CY-M64x6/W*D-Special