Flange applications

Flange applications

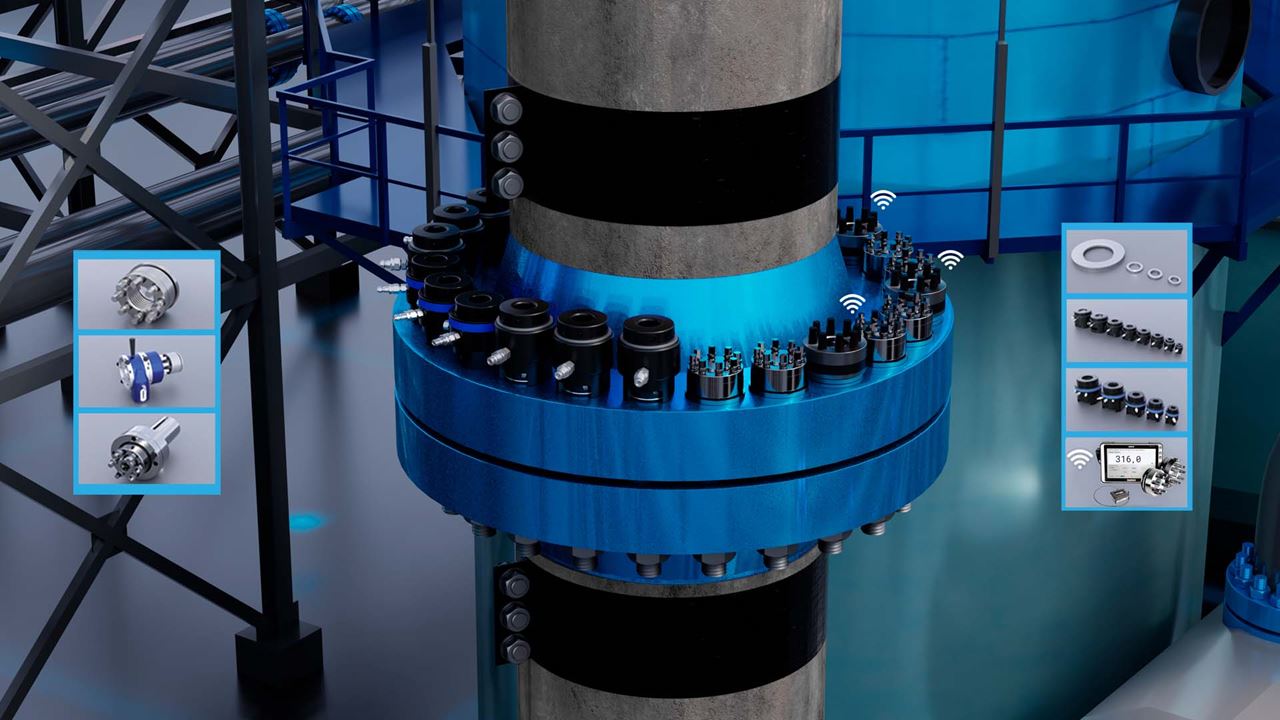

Since flange applications are so prevalent throughout oil & gas refineries, their importance is paramount. Flexing, shock loading, and achieving the correct preload are among the most challenging issues. No matter the flange type, no matter the issue, Nord-Lock Group can help solve even your most difficult flange application needs.

Common issues

Large flanges are present throughout oil & gas refineries, and they bring many challenges. Their bolted joints are subject to loosening, with settlement and relaxation causing a loss of preload. Larger bolts require bigger (and often more cumbersome) tools, which can render them ineffective and unsafe. Nord-Lock Group’s many solutions facilitate a fast, safe, and accurate means of properly preloading and securing bolts. Further, two of our recent innovations – the Load-Sensing Tensioner and Load-Sensing Flexnut – allow for both initial and ongoing remote preload monitoring.

Severe vibration on soft metals, composites, and polymers can loosen the bolted joints used to secure flanges. Not only does this adversely affect operational reliability and production, but it can also lead to an increased risk of accidents and personal injury. High-quality Nord-Lock Group solutions are tough enough to handle the environmental challenges of downstream oil and gas applications.

Flanges are the most common connection components between refinery equipment and pipes. Once flexing causes the sealing of a flange to be compromised, dangerous materials can leak out and cause severe fire, injuries, and deaths. Nord-Lock Group solutions mitigate these issues, allowing you to properly seal all flanges.

Shock loading refers to a sudden and drastic load increase, which can affect the durability of the flange and its bolts or cause an immediate and harmful break. Our Superbolt solutions enable fast and accurate application of torque to multiple jackbolts and provide even jackbolt load application to minimize the effects of shock loading.

A number of refineries are located in coastal regions where corrosion, rust, and exposure to chemicals threaten secure connections. Nord-Lock Group provides state-of-the-art solutions for even the harshest environments.

Our broad range of fastening solutions incorporates a wide variety of tough materials, including options treated with corrosion-resistant coatings to stand the test of time.

Loosened or weakened bolts can result from improper tightening or problems associated with soft contact surfaces. Nord-Lock Group solutions solve these common issues with our industry-leading technologies – including Nord-Lock wedge-locking washers and cutting-edge Superbolt and Boltight tensioning products, all of which prohibit unintentional loosening.

Case studies

Contact us to discover solutions for your bolting challenges

These pages are specific to customers working in downstream environments, for more oil & gas industry bolting solutions please click here.