Extending the Service Life of Studs and Bolts Exposed to Dynamic Loads

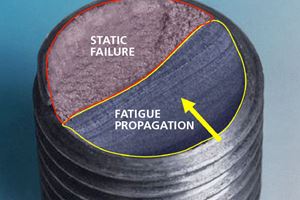

One of the most common failure mechanisms for bolted connections is fatigue – a phenomenon that typically occurs in bolts/studs exposed to dynamic loads that are often inferior to the Ultimate tensile strength (RM) or the Yield strength limit (Re).

Reasons for fatigue include:

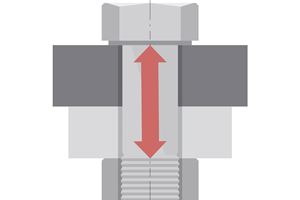

- Applied preload is lower than the dynamic loads the joint is exposed to.

- Loss of preload due to settlements and/or spontaneous bolt loosening.

- Poor elasticity in the joint.

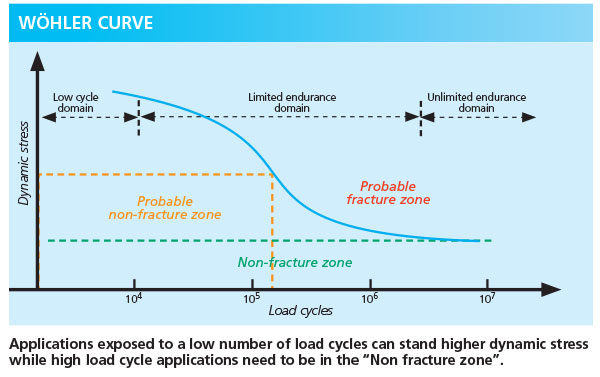

To avoid fatigue failure a preload high enough to cope with the external dynamic loads is recommended. However, a preload that is too high may also shorten the life of a bolted connection if the yield point or ultimate tensile strength is exceeded. It is therefore of utmost importance to have good control of the tightening process. Increased elasticity will also increase the service life of the stud and it is commonly known that a long and thin bolt is better than a short and thick one.

To avoid fatigue failure a preload high enough to cope with the external dynamic loads is recommended. However, a preload that is too high may also shorten the life of a bolted connection if the yield point or ultimate tensile strength is exceeded. It is therefore of utmost importance to have good control of the tightening process. Increased elasticity will also increase the service life of the stud and it is commonly known that a long and thin bolt is better than a short and thick one.

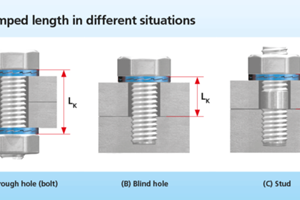

As a guideline, the free clamp length divided by the thread diameter should be at least 3 but preferably above 5. For small and medium-sized bolts Nord-Lock wedge locking washers are a cost-effective solution in order to increase the life and security level of a bolted connection. As it is possible to lubricate the threads without jeopardizing the locking function, you will achieve the desired preload and still be able to maintain it, even when exposed to severe vibration and dynamic loads.

For larger thread sizes, Superbolt multi-jackbolt tensioners (MJTs) are the optimum solution, since they combine high tightening precision with increased elasticity, equal to 2-3 times the thread diameter.