The Experts: Picking up the slack

Why is slackening becoming an increasing problem?

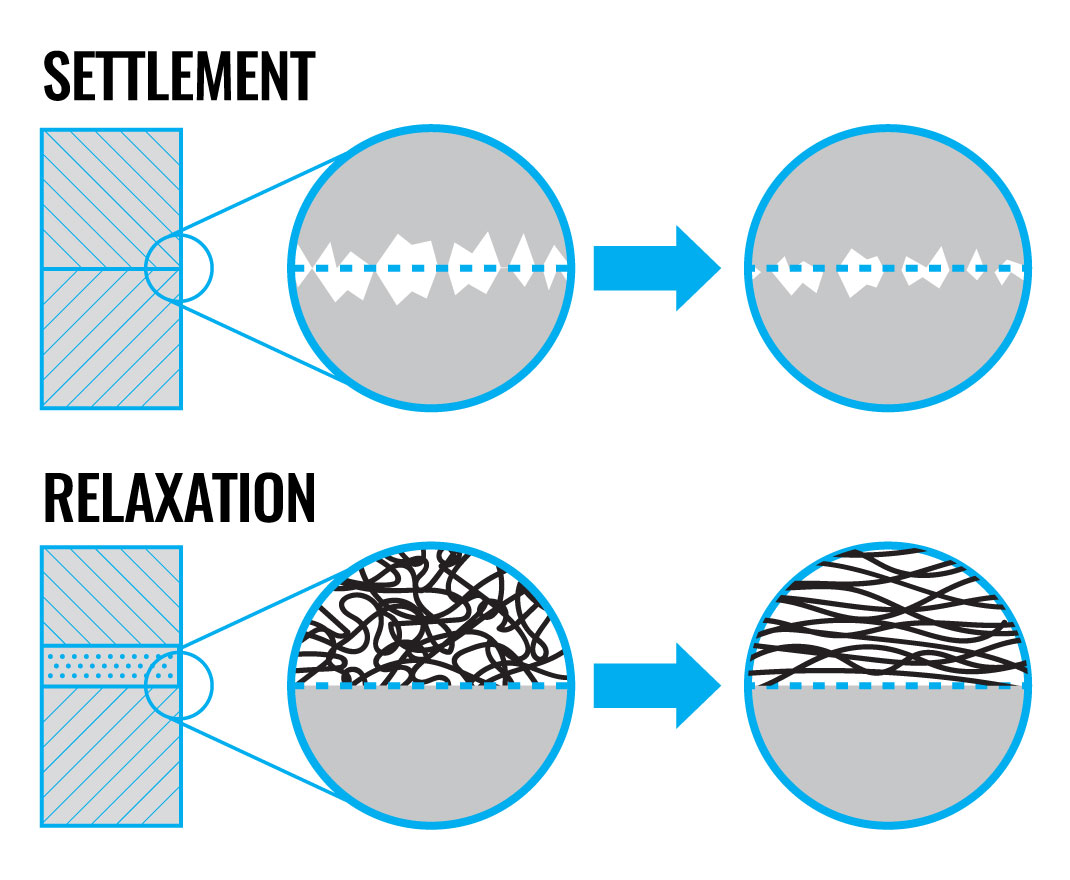

One of the main reasons for bolt loosening is slackening. Slackening leads to loss of preload and can be divided into three subgroups: Slackening caused by settlement, slackening due to relaxation over time or slackening resulting from gradual temperature changes (creep).

Settlements are related to surface roughness and surface irregularities. The pressure on the clamped surfaces after pre-loading causes any irregularities on the surface to start to flatten. When the irregularities have been flattened out the parts will be less tightened and the pre-load will decrease. If the reduction of pre-load is significant enough the joint may rotate loose. Low pre-load also increases the risk of fatigue failure.

Settlements are related to surface roughness and surface irregularities. The pressure on the clamped surfaces after pre-loading causes any irregularities on the surface to start to flatten. When the irregularities have been flattened out the parts will be less tightened and the pre-load will decrease. If the reduction of pre-load is significant enough the joint may rotate loose. Low pre-load also increases the risk of fatigue failure.

Relaxation occurs when materials become more compact over time, resulting in additional loss of pre-load. This is common for materials such as polymers, composites, copper and soft metals.

Creep is the tendency of a solid material to move slowly or deform permanently under the influence of stresses. It occurs as a result of long-term exposure to high levels of stress that fall below the yield strength of the material. Creep is more severe in materials that are subjected to heat for long periods, and close to their recrystallization temperature. Creep always increases as the ambient temperature rises.

Today, increasingly more joints are exposed to more extreme conditions such as higher speed, high temperature and higher loadings. If components were still manufactured out of steel the ’old way’, they would be cumbersome and heavy. In order to reduce the total weight, components these days are made from composites, plastics and aluminium. This is why slackening is becoming an increasing problem. Nord-Lock has developed the X-series washers to counteract these slackening effects so designers no longer have to worry about how to compensate for slackening in the joints.

ASK THE EXPERTS

Do you have a question about bolt securing?

Put the Nord-Lock experts to the test.

Email your questions about bolt securing to

experts@nord-lock.com