The Experts: Superbolt – your flexible friend

How does the added flexibility of Superbolt improve the bolted joint?

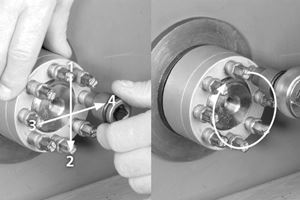

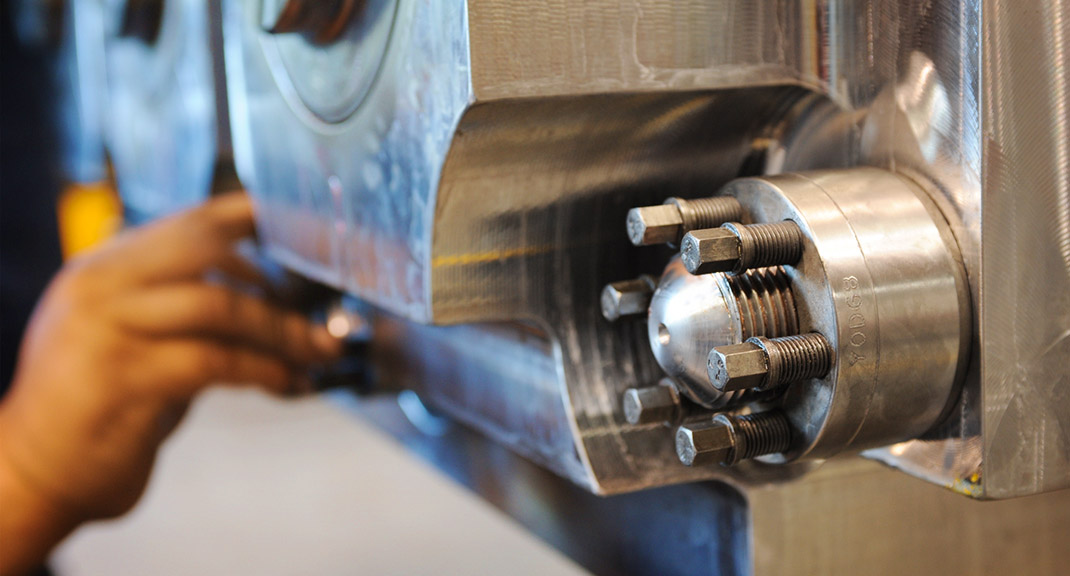

In normal bolted joints, the stress concentration of loads on the first 1-2 threads is one of the main reasons why a bolted joint fails. With a joint utilizing Superbolt multi-jackbolt tensioners, as the jackbolts are torqued to stretch the stud/bolt, the tensioner body radially flexes in at the top and flexes out at the bottom. This flexing action transfers the load from the first few threads and distributes the load evenly throughout the entire engaged thread length between the tensioner and stud/bolt. This simple flexing action dramatically increases the strength of the joint by reducing the stress concentrations on the first couple of threads.

In addition, this radial flexing action combined with axial flexing results in added elasticity in the joint. In a typical bolted joint, the average clamp length of the joint is around 2 to 5 thread diameters in length. The combined flexing in the MJT creates a higher load point, which increases the clamp length of the joint by as much as 2-3 thread diameters. It can be concluded that the Superbolt tensioner could double the elasticity of a standard bolted joint. This eliminates the need for lengthening the bolt/stud and adding a spacer or multiple spring washers, (both of which can be costly), to improve the elasticity of the joint.

In addition, this radial flexing action combined with axial flexing results in added elasticity in the joint. In a typical bolted joint, the average clamp length of the joint is around 2 to 5 thread diameters in length. The combined flexing in the MJT creates a higher load point, which increases the clamp length of the joint by as much as 2-3 thread diameters. It can be concluded that the Superbolt tensioner could double the elasticity of a standard bolted joint. This eliminates the need for lengthening the bolt/stud and adding a spacer or multiple spring washers, (both of which can be costly), to improve the elasticity of the joint.

Do you have a question about bolt securing?

Put the Nord-Lock experts to the test.

Email your questions about bolt securing to

experts@nord-lock.com