Expander system ensures long-life for excavators

We all expect our roads to be smooth, our pavements unrutted, to have running water, electricity, gas, and telecommunications in our homes and offices and yet many of us probably pay little attention (except to get annoyed because of the noise!) to the excavators that lay the roads and these vital underground networks.

Montchanin, a town about two-thirds of the way down from Paris to Geneva in the French region of Bourgogne, is home to a successful family-run SME with 250 employees: Pascal Guinot TP (which stands for Travaux Publics or public works). The company, founded in 1993, not only digs the trenches but also lays dry networks (electricity, heating, telecommunications) and wet networks (water and sewerage) inside them and then fills them in and repairs the road. It also does earth-moving works, lays roads and pavements, builds outdoor parking lots and will do work for individual customers who want to organize a courtyard, for example.

Costly and time-consuming repair

“Our clients are municipalities, SMEs, industrial groups and, occasionally, private customers.” says Thomas Desmerger who is responsible for the company’s maintenance workshop.

Pascal Guinot TP has about 800 different machines with which do this work. These include 70 excavators and mini-excavators “which are in use 45 weeks a year,” says Mr. Desmerger. “We outright own about half of these excavators of various different brands such as New Holland, Liebherr, Caterpillar, JCB and Mecalac,” he explains, “whilst the others are on a rent-to-own basis with a maintenance contract. So by the time we own them, these vehicles are about mid-way through their 10-year average lifespan, and are no longer covered by the maintenance contract so that’s when we have to start maintaining them ourselves. And because they’re five years old they start needing major repairs!”

The boom, arm and bucket are the parts that most suffer from wear-and-tear on these excavators but the pivot pin on the arm is the principal problem. “When the arm becomes a bit wobbly it makes it hard for the operator to control and then he can’t dig or scoop precisely,” Mr. Desmerger explains. The wobble comes because the pivot pin has become worn and so no longer fits snug and tight in the lug ears. “In the past we would have to dismantle the part, do some welding, have some line boring done, and then put it all back together... which usually meant the machine was out of action for at least a month. And if a machine is down then it’s not earning us any money,” he adds. “The most expensive part of this operation was the machining because that was something that we couldn’t do ourselves and it was costing us a small fortune, sometimes €2,000 for a single pivot pin,” he remarks.

Shortening the downtime

Before Mr. Desmerger joined Guinot TP he was already familiar with the Nord-Lock Group Expander System. “I’ve been in this business for more than 20 years so I knew about Nord-Lock products,” he smiles. So he suggested that Expander System pivot pins might be a solution to shortening the downtime of these excavators. “I contacted Nord-Lock Group and discussed our problem and got a solution.”

His workshop does a lot of predictive maintenance so that during the two principal periods when work is slow (January and February because of the weather and August when many are on holiday), the excavators can be fixed quickly. “So, when the operator begins to feel that the pivot pin is getting a bit loose then we take all the necessary measurements, communicate them to Nord-Lock Group and they supply us with a fix. We’ve been using the Expander System for about three to four years and we always get an answer and a follow-up from Nord-Lock Group, they’re very professional,” he says.

“Our aim was to prolong the life of our machines and to

reduce their costs,” he says. "Today, thanks to the Expander System the downtime of our machines has been provided by three, down to around 10 days, so the money is very well spent." Mr Desmerger stresses.

Business: Public works and civil engineering

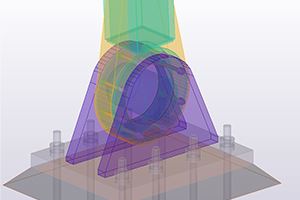

Application: Excavator arms

The solution: Nord-Lock Expander system

The results: Prolonging the life of the machines, cost reduction, sharp reduction of downtime