What do I need to know about the Circular Economy?

For engineering, construction and other steel heavy industries, we’re relying on the extraction of virgin materials. Even iron ore, one of the most abundant metals on earth, should not be taken for granted as an economically viable commercial resource forever. Steel is also particularly carbon intensive, so there’s an economic and environmental drive towards the circular economy.

What is the circular economy? A quick history of production

The industrial revolution, followed by globalisation and the information age, delivered cheap mass production and almost limitless possibilities to consume. But with finite natural resources, our world simply cannot sustain the levels of electronics, plastics, machines, foods, and textiles that are disposed of each year.

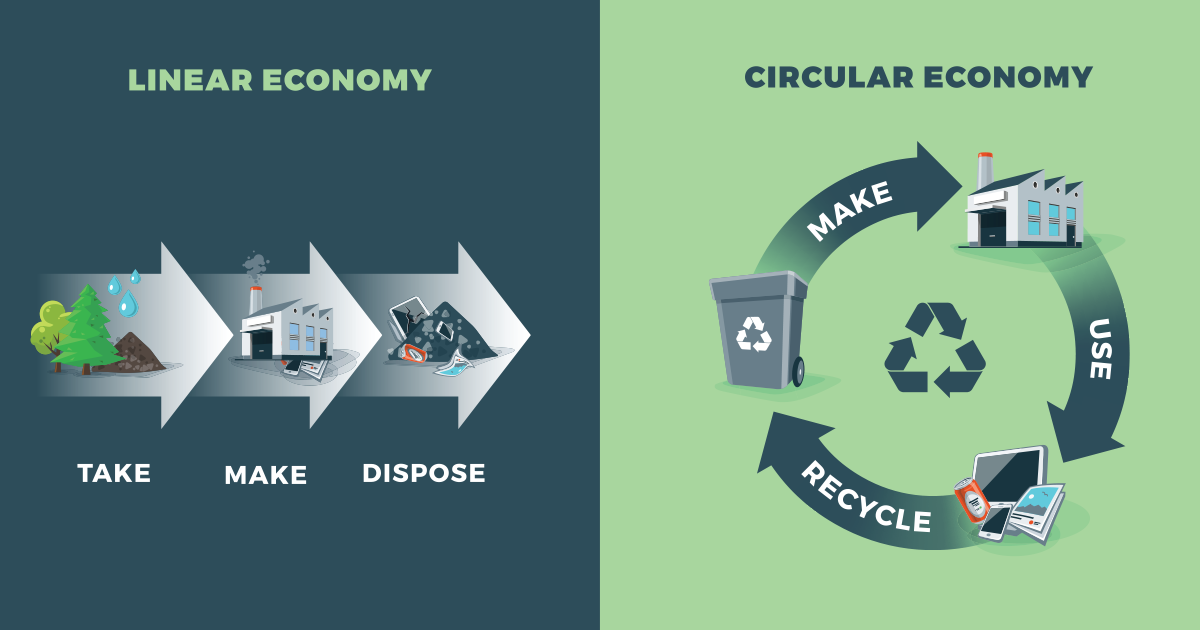

For half a century we have operated in the linear economy. Raw materials are sourced, then products are designed, manufactured, marketed, and shipped with a focus on the end-user and a singular purpose. But when that product has served its purpose, or is succeeded by a newer model, it is often trashed. So, our economy is built on waste, quite different from the resourcefulness and durability that were so valued in early 20th century society when people mended, reused and repurposed possessions more commonly.

Now, by looking beyond the take-make-waste model, the circular economy can fundamentally reshape the way society thinks about progress. It’s about using things, rather than using them up - finding sustainably sourced materials and redesigning products, equipment, and infrastructure to be long-lasting and recyclable, or preferably returned, disassembled and the components reused by the original manufacturer.

Circularity therefore offers us a method of reducing waste and at the same time requiring less extractive with virgin raw materials to make goods.

So, how do we achieve a circular economy?

The simple answer: by circular design.

Radjou and Prabhu’s book ‘Frugal Innovation’ states that “over 70% of a product’s life-cycle costs and environmental footprint is determined during its design phase.”

If you are a designer, you are tasked with a difficult balancing act. Of course, you need to zoom in on the user's functional needs, the product still needs to have the right properties to work. But to make it circular you also need to consider the environmental impact of each component through its entire lifecycle. How are your materials sourced/transported? How is a long-lasting lifetime, reuse, repair, or refurbishment built into the design? How easy is it to disassemble the finished goods to repurpose components?

The aim of circular design is to keep materials in use at their highest value, bringing them back to original manufacturers for reuse in a new application – rather than becoming waste. Can steel from one solution be retrieved, melted down and reused in the next model? In its totality, you’re looking to design a lean, closed loop system where ‘less is more’.

What is a closed loop system?

The circular economy embraces the cyclical order of the natural world, taking insight from living systems where one species’ waste is another’s food. Renewable energy comes from the sun, things grow, die and eventually nutrients return to the soil – a sustainable flow of materials that works.

In circular design, resource use and waste should be minimal. The loop is only 100% closed by bringing products back to their manufacturer, breaking them down into composite parts and reusing every element in another process – one that itself is also circular.

Of course, this is very complex, and much easier said than done. Not only does it require comprehensive tracking of a product’s components and close quality control over reused materials – it also demands you to have a new purpose for everything that is returned. Or at least you need another organisation or industry that would be willing to purchase the recycled resources that your own company cannot make use of.

It’s for these reasons that advocates of circular design recommend you take an iterative approach. Thus, you look at where it’s easiest to get started and, step by step, try to close the loop.

Collaboration throughout the value chain

All those companies interconnected in a product’s supply chain should adhere to the principles of circular design if you are to fulfil the circular economy. It’s not about individual manufacturers rethinking their products; rather it demands a transformational partnership across all sectors.

You’ll need to use sustainably sourced inputs, transport goods with vehicles powered by renewable energy, use compostable packaging, track and cycle valuable materials using product passports and develop entirely new returns policies for customers.

A successful transition to the circular economy depends on a commitment from all stakeholders, which is where the business case comes in. Once you realize that you’re being more resourceful with raw materials, reducing both waste and your input costs – the challenges to accomplish your circular goals become much easier to tackle.

The Ellen MacArthur Foundation estimates the global market for sustainable products to be worth a trillion dollars. Plus, in cost-strained developed economies a more resourceful approach to manufacturing, particularly for mineral intensive businesses, might be a wise strategy to help companies survive and thrive in the long-term.

Rethinking business models: from ownership to licensing

The circular economy might overhaul how ownership works, with goods instead licensed rather than purchased from manufacturers who happily retrieve the products to be regenerated in the next model or sold for a revenue.

For example, Philips installed the lights at Amsterdam’s Schiphol airport Lounge 2 for free and will remain responsible for maintaining/upgrading the physical system, instead charging the customer for the service of lighting. Now Philips are incentivized to build a lighting system that is easily repairable, long-lasting and reusable – because this saves them money now and in production of the next lighting version.

Perhaps soon you will rent sustainable footwear, paying a subscription for regular new shoes based on returning the fully recyclable used one. This economic model will challenge our material consumption habits, a change in behaviour that many would argue is a healthy psychological shift and one that is already shaping the sustainability strategies of leading consumer brands.

A global solution

An increasing proportion of people want sustainable products; municipalities are incentivized to reduce waste and manufacturers want to create value in the supply chain – three objectives that can all be achieved in the profound shift to a regenerative circular economy.

It’s an idea that’s gaining momentum, from books to boardrooms, and the result could be a more sustainable world, for everyone.