Joint Guide

|

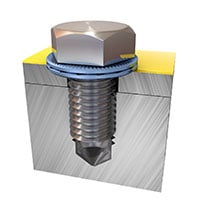

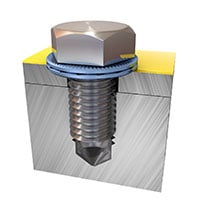

Tapped holes

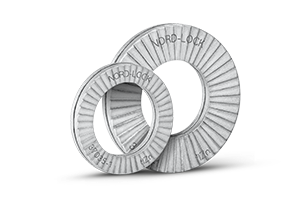

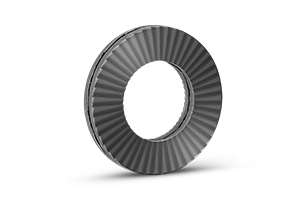

Nord-Lock X-series washers safely lock the bolt against the underlying surface.

|

|

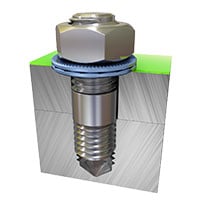

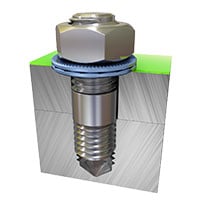

Counterbores

The outer diameter of Nord-Lock X-series washers is designed for counterbore holes (i.e., the washers fit under the head of standard bolts).

|

|

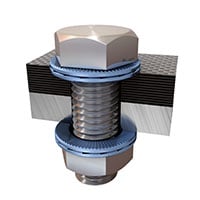

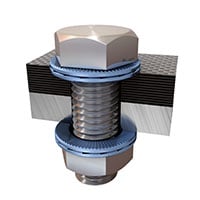

Through-holes

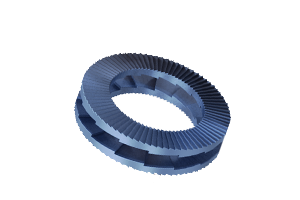

As for all locking washers, through-holes require two pairs of Nord-Lock X-series washers — one pair for securing the bolt and a second pair for securing the nut.

|

|

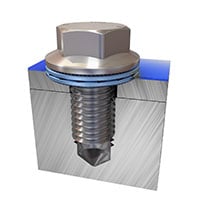

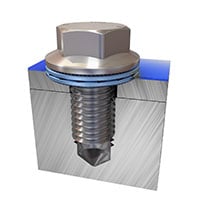

Stud bolts

Nord-Lock X-series washers safely lock the nut on stud bolts and eliminate the need for adhesives.

|

|

Applications with large / slotted holes

To optimize the load distribution for applications with large/slotted holes, use a flanged nut/bolt together with Nord-Lock X-series “SP” washers with enlarged outer diameter.

|

|

Designs where Nord-Lock X-series washers are not recommended:

- Mating surfaces that are not locked in place (see left figure)

- Mating surfaces harder than the washers

- Wooden mating surfaces

- Non-preloaded joints

|

Selection Guide

Nord-Lock X-series washers are currently available in the following material:

| Application parameter: |

Steel |

| Steel type: |

EN 1.7225 or equivalent |

| Examples of applications: |

General steel applications |

| Washer types: |

Regular outer diameter

Enlarged outer diameter |

| Treatment surface coating: |

Through hardened Delta Protekt® base coat (KL100) and top coat (VH302GZ) |

| Corrosion resistance: |

Minimum 1,000 hours in salt spray test (according to IS09227) |

| Bolt grades: |

8.8 and 10.9 |

| Temperature range: |

-40°C to 150°C

Temperature recommendations based on information from the raw material supplier. Locking function not affected within the specification.

|