Torquelator by Nord-Lock

Torquelator by Nord-Lock

Frequently Asked Questions

|

|

| Q. How do you calculate using Kellerman&Klein? |

|

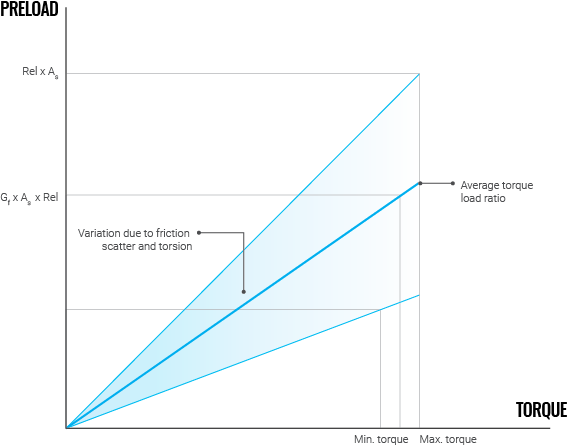

A: Nord-Lock is using the Kellerman & Klein formula to calculate the relationship between torque and preload. It uses average values of the friction coefficients. Nord-Lock has added a tightening ratio to the Kellerman & Klein formula. This ratio is based on our long experience of securing bolted joints and should be viewed as a security margin. It is set to minimize the risk of overstretching the bolt while at the same time making sure the clamp load is enough to get wedge-locking effect. Formula: T0= F0×(0,159×P+0,583×d2×μT+rm×μH) [Nm]

|

| Q: What is the tightening ratio, GF? |

|

A: When tightening according to guidelines and with no deviation, this is the pre-stress achieved expressed as % of yield point. The tightening ratio in this app can be set between 0 to 100%. Too low clamp load may lead to sliding or separation of parts. Too high clamp load may lead to deformation of parts or overstretched bolts. Torsion, variation in friction, scatter for the tightening tool and maximum acceptable tensile stress levels need to be considered when deciding tightening ratio. |

| Q: How do you calculate using VDI 2230? |

|

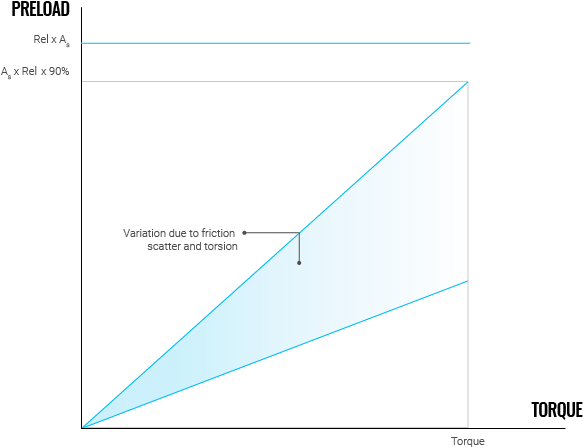

A: VDI 2230 is using the same Kellerman&Klein formula but is using minimum values of the friction coefficients and is calculating a torque corresponding to a clamp load utilizing 90% of the yield point of the bolt. The calculation consider both tensile and torsional stress. The calculation does not take into account deviations during tightening.

|

| Q: Which calculation standard should I use? |

|

A: If you do not know which one to use, we recommend you to use Kellerman&Klein. These guidelines have been used successfully in more than 35 years and are working well together with our washers. VDI2230 becomes more and more common in the world but has been used in some European countries for a long time. If you feel insecure, you can always contact us for a deeper analysis. |

| Q: What friction values have you used when choosing oil? |

|

A: If you save the calculation you will see a summary and then it is written what values we have used in the calculation. If you do not think they are representative of your bolted connection. Make another calculation and choose custom, to fill in your own values. |

| Q: What is the tool accuracy? |

|

A: No matter what tightening tool you are using, there will always be a scatter. Tool accuracy for common tools, according to NF E 25030-1:

|

| Q: What thread pitch have you been using? |

|

A: When you save the calculation you will see what thread pitch has been used. |