How wedge-locking washers work

How wedge-locking washers work

Tension creates a self-locking bolt. Nord-Lock washers secure bolts with tension instead of friction.

The Junker vibration test

The Junker test is considered the most severe vibration test for bolted connections. In this video, we compare the performance of Nord-Lock washers with other locking methods. It will give you a clear indication of how wedge-locking washers work.

The loosening of bolted joints has been a problem ever since the bolt was invented, prompting numerous studies on the phenomenon. In the 1960s, German professor Gerhard H. Junker discovered that shear loading perpendicular to the fastener axis is the most severe form of loading for vibration-induced loosening. The testing method he devised, in which a joint is mounted on a test rig and exposed to a simulated vibration at a right angle to the joint, subsequently became a DIN standard – DIN 65151 – and is commonly known as the Junker test.

To prove the reliability of its products, Nord-Lock runs 10 000 Junker demonstrations worldwide every year, in the presence of its customers. In addition, nearly 100 customer-specific Junker tests are carried out in Nord-Lock’s laboratories every year.

The Nord-Lock principle

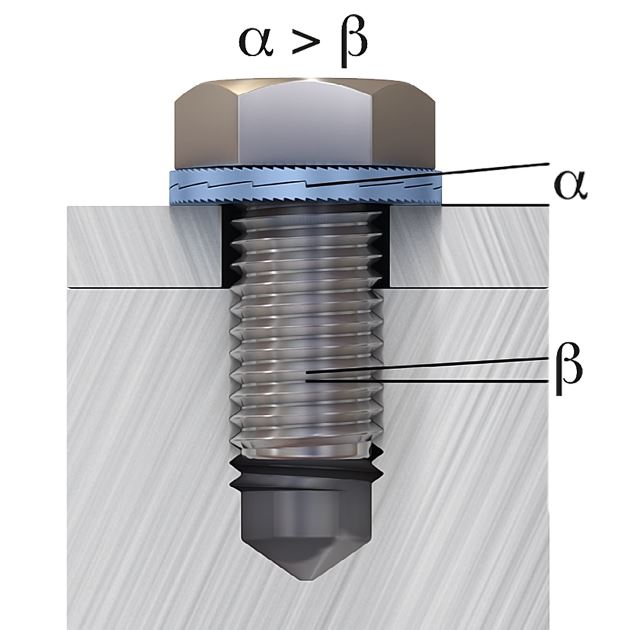

Nord-Lock washers secure bolts with tension instead of friction. The system cannot loosen unintentionally as it creates a wedge-effect underneath the bolt head or nut.

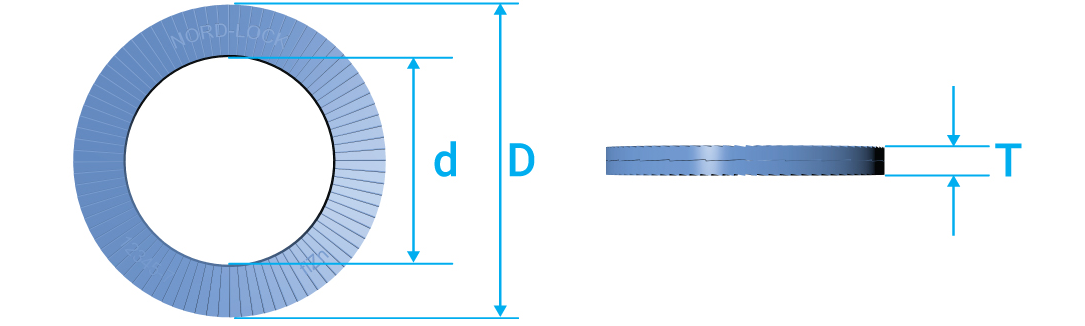

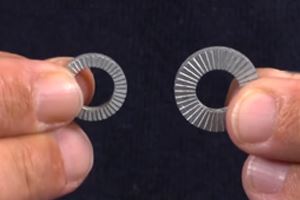

The system comprises of a pair of wedge-lock washers with cams on one side and radial teeth on the opposite side. The key is the difference in angles.

Since the cam angle "α" is larger than the thread pitch "β", the pair of wedge-locking washers expand more than the corresponding pitch of the thread creating a wedge effect which blocks any attempt from the bolt/nut to rotate loose.

When the bolt is tightened, the teeth grip and seat the mating surfaces. Nord-Lock washers become locked in place, allowing movement only across the face of the cams.

Any attempt from the bolt/nut to rotate loose is blocked by the wedge effect of the cams.

Benefits of using Nord-Lock washers

- Reliable locking, even for joints with short clamp length

- Quick and easy to install and remove

- High corrosion resistance with Delta Protekt®

- Locking function not affected by lubrication

- Reusable

Nord-Lock washers are available in:

Steel

- For general applications

- Standard outer diameter: M3 - M42 (metric) and #5 - 1 1/2" (inches)

- Enlarged outer diameter: M3.5 - M36 (metric) and #6 - 1 3/8" (inches)

254 SMO® stainless-steel

- For applications in corrosive environments

- Standard outer diameter: M3 - M39 (metric) and #5 - 1 1/2" (inches)

- Enlarged outer diameter: M3.5 - M27 (metric) and #6 - 1" (inches)

Click here to see available washers

Find your washer size

View product list to determine the required washer size for your bolt.