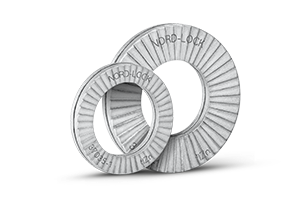

Nord-Lock Washers in Junker Vibration Test

In this video we compare the performance of Nord-Lock washers with other common bolt locking methods, including plain washers, helical spring washers, check lock nut, nylon insert nut, and double nut.

The Junker test is considered the most severe vibration test for bolted connections (according to international standards DIN 65151 and ISO 16130).