Why Use Wedge-Locking Instead of Friction-Based Locking?

What is the difference between friction-based locking and wedge locking, and when is lubrication needed?

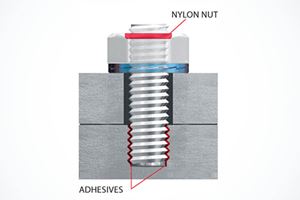

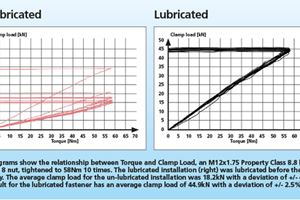

The principle of friction locking is based on increased friction in the thread or under the bolt head/nut. The main disadvantage of this method is increased torsion stress in the joint. High torsion may cause the fastener to yield at a lower preload than expected. Since friction conditions are uneven you may not reach the necessary preload. Insufficient preload is the most common cause of the bolt’s failure, often due to fatigue. Lubricants are often used to minimize friction and to obtain uniform clamp load. However, lubrication will significantly reduce or even discharge locking ability of any friction-based method. Friction-based locking results in little or no control over achieved clamp load.

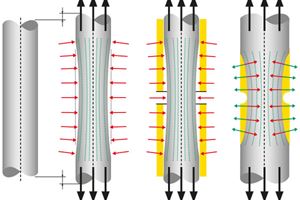

The wedge locking method is based on tension instead of friction. The most common example of the wedge locking system is a pair of washers that have cams with a rise greater than the thread pitch of the bolt. The washer pair is installed cam face to cam face. When the bolt/nut is tightened teeth grip and lock the mating surfaces, allowing movement only across the cam faces. Any rotation of the bolt/nut is blocked by the wedge effect of the cams. The wedge locking ability is not affected by lubrication; furthermore, by using it, you can utilize each bolt to its full capacity.

Which bolt locking product should I use?

Get your free eBook on the topic of bolt loosening and see how different bolt locking products perform.

What you will find in the eBook:

- Pros and cons of the different bolt locking methods

- Evaluation of different products

- A print-friendly Guidance for Selection, to help you decide which product to use in your applications