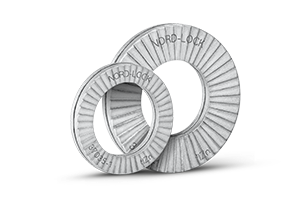

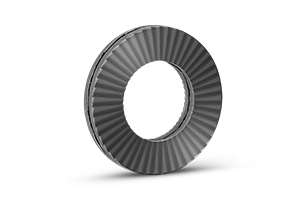

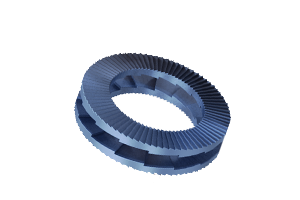

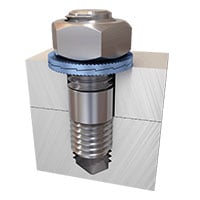

Nord-Lock Original Washers

Nord-Lock Original Washers

Joint Guide

|

Tapped holes |

|

Counterbores |

|

Through-holes |

|

Stud bolts |

|

Applications with large / slotted holes or soft underlying surfaces |

|

Designs where Nord-Lock washers are not recommended

|