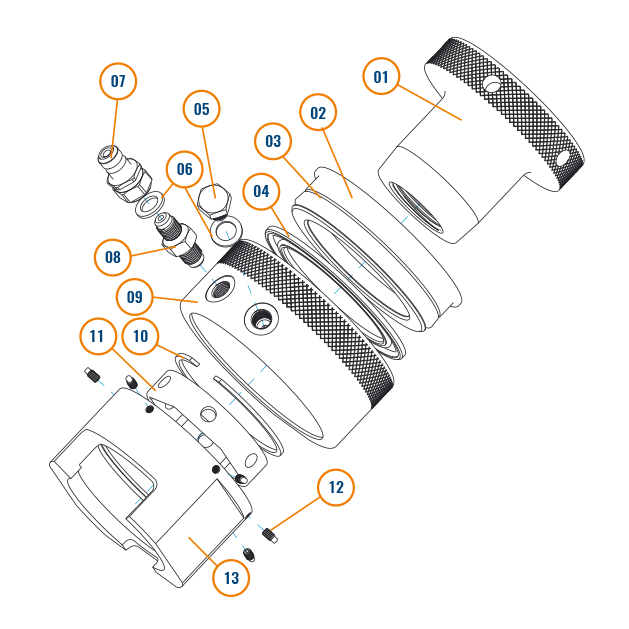

Designed to fit most ANSI B16.5, MSS SP44 and API17D flanges. Compatible with metric and imperial bolts from ¾” (M20) – 4” (M100).

|

|

Features

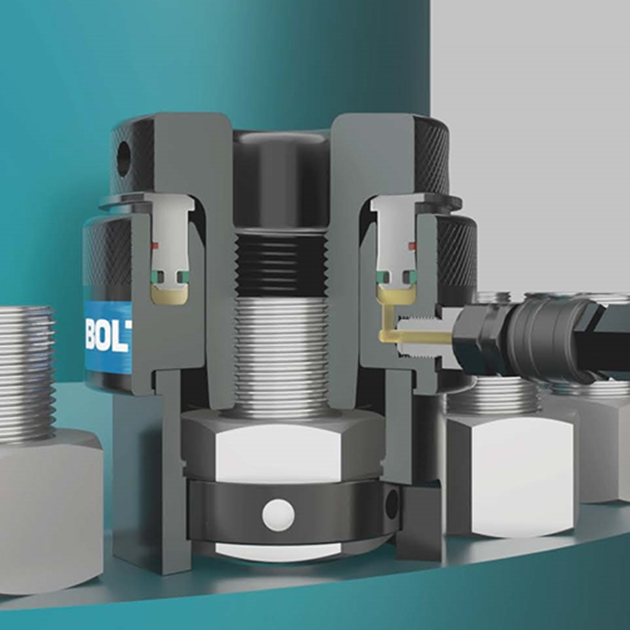

- 1500 bar MWP

- 15mm stroke

- Profiling for weight saving

- Quick release bridge

- Single or twin port options

- Long life composite seals

Advantages

- Easy to install and remove

- High wear and corrosion resistant surface treatment

- Extremely durable due to surface coating of components (Nitride)

- Internal features to compensate for joint misalignment

- Tools can be connected in sequence improving operation speed and ensuring even joint compression

- Available from stock

Testing & Certification

Boltight is LRQA certified for quality and environmental assurance to ISO 9001: 2015. All tools are assembled, filled with oil and pressure tested prior to despatch.