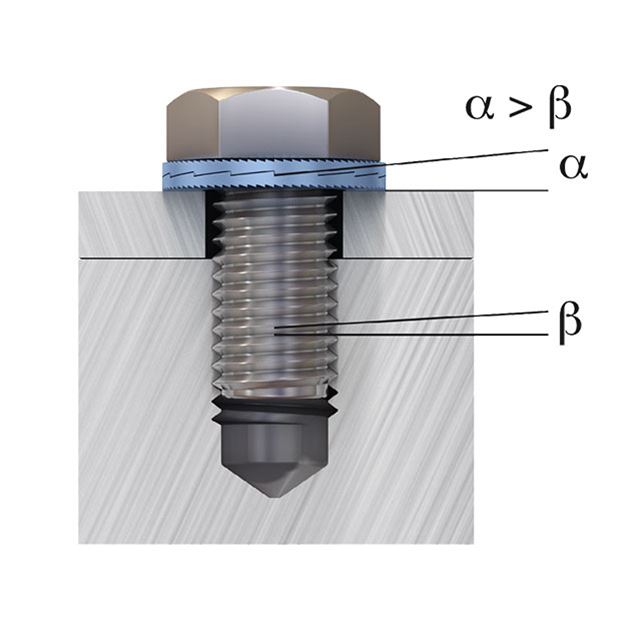

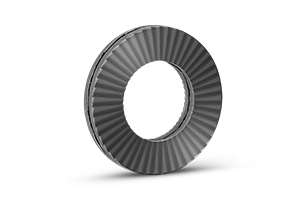

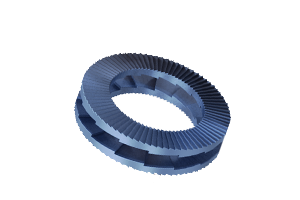

Tightening

When the bolt and/or nut is tightened, the teeth grip and seat the mating surfaces. Since the cam angle α, is larger than the thread pitch β, a wedge effect is created by the cams, preventing the bolt from rotating loose. The Nord-Lock wedge-lock washer is locked in place, allowing movement only across the face of the cams. Any attempt from the bolt/nut to rotate loose is blocked by the wedge effect of the cams.

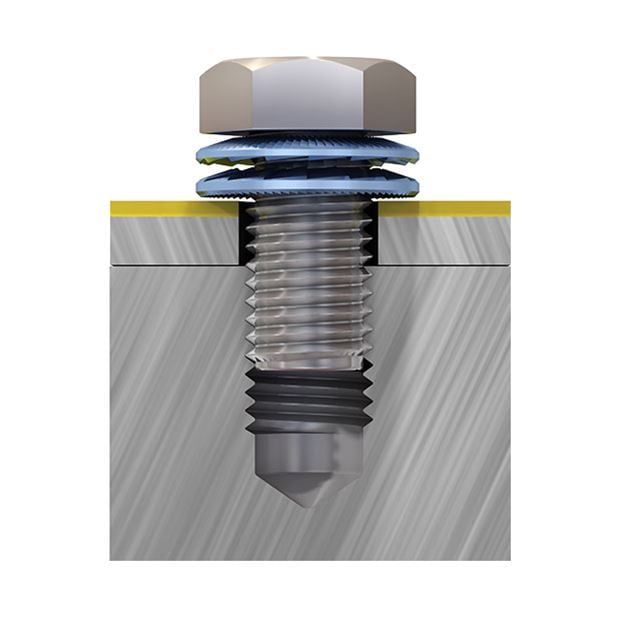

Untightening

When a bolt is untightened with a wrench, the pair of washers expand more than the corresponding pitch of the thread, allowing the bolt/nut to rise. Nord-Lock wedge-lock washers positively secure the fastener in a joint which is subjected to any kind of vibration or dynamic loads.

Features

- Standard range available for bolt sizes M3 - M130

- Washers available in 5 different materials - steel, stainless steel, 254 SMO®, INCONEL® / HASTELLOY® and C-276 INCONEL® 718

- Washers available with enlarged outer diameter (SP washers)

- Reliable bolt securing system at high and low clamp loads