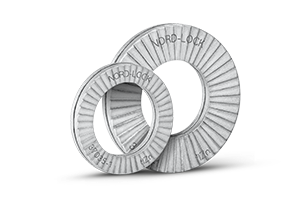

Directives sur les couples

Utilisez nos directives pour obtenir une indication des valeurs de couple et de précharge pour les boulons de toutes tailles M3 - M42, en utilisant des rondelles Nord-Lock et une variété de méthodes de lubrification. Veuillez noter que les valeurs peuvent varier en fonction des systèmes de revêtement et des coefficients de frottement.