Superbolt was already the standard for rope shovels at the mining operation in Carajás, Brazil. Removing and remounting the brand’s multi-jackbolt tensioners from the heavy-duty machines’ sideframes was nothing new for a maintenance session like the one in July 2025. Using the Superbolt Tool to loosen and tighten them, however, was new.

The mine’s vendor for heavy machinery parts, Grupo Hidrau Torque (GHT), was aiming to upgrade the installation and removal processes. As one of Latin America’s leading distributors of replacement and spare parts for industries like mining, GHT understood that solutions raising maintenance efficiency would also reduce downtimes for machines and increase its clients’ productivity and bottom line.

According to José De La Cruz, Nord-Lock Group’s Sales Manager for Superbolt in Latin America, many firms like GHT appreciate how replacing the enormous bolts typical for powerful equipment, such as rope shovels, with Superbolt tensioners makes things easier and safer.

“The Superbolt system removes the need for large conventional tooling,” he says. “You can just use a regular torque wrench.”

Yet, dismounting and reinstalling the tensioners can still be tedious and time-consuming. “Customers were asking how to further speed up the process,” explains De La Cruz, “it’s a perfect use-case for the Superbolt Tool.”

“The Superbolt Tool just comes in and tightens them all at once at the same time.”

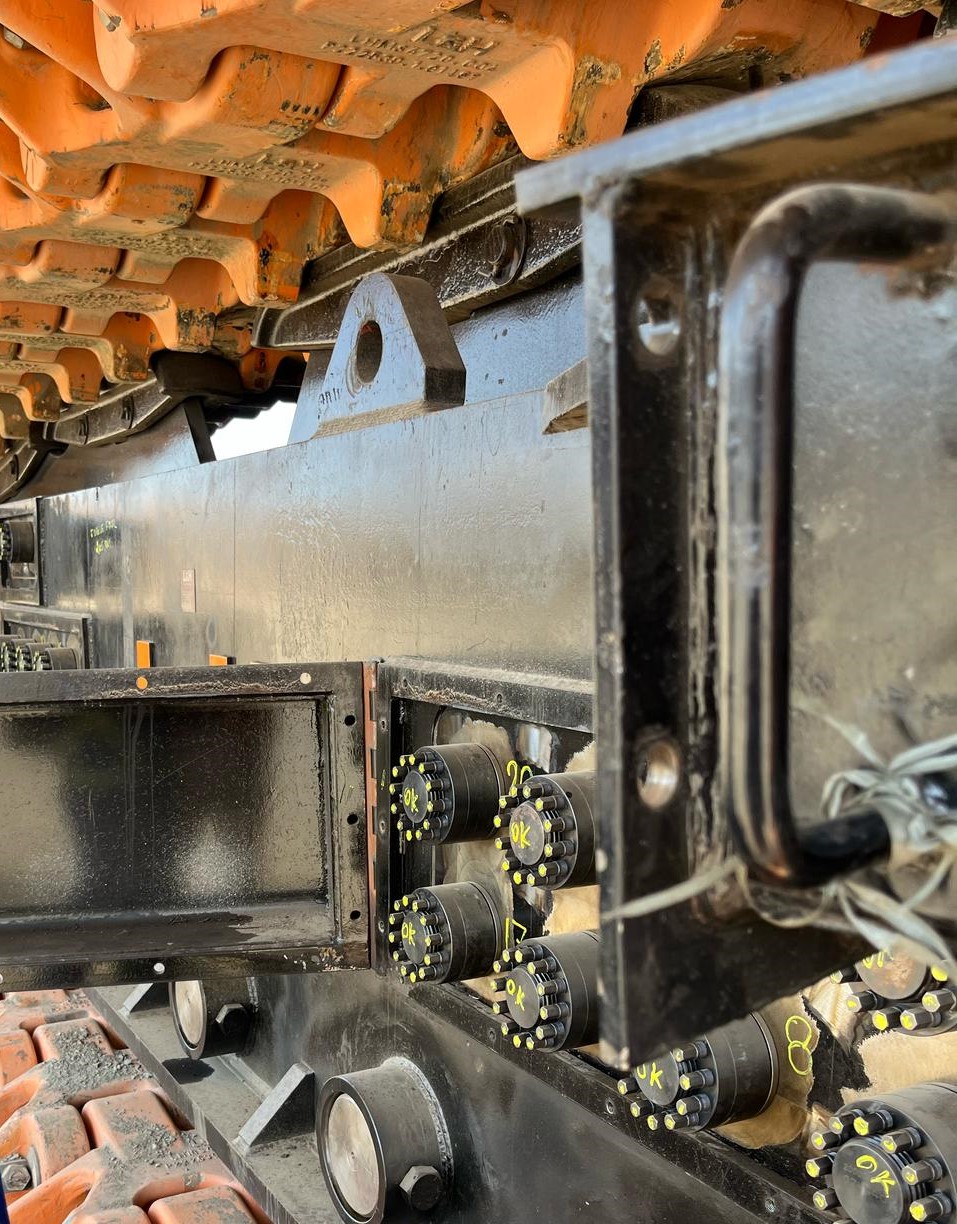

Superbolt technology uses multiple mechanical jackbolts encircled in the body of a nut to create a secure bolted connection. It remains fixed against serious vibrations and extreme conditions that have previously required giant threaded bolts weighing up to 100 pounds (45 kilograms). But since the jackbolts are smaller, they can be tightened with simple hand tools to generate the clamping force that holds the tensioner in place.

“It generates a precise and uniform clamping force, eliminating concerns about thread friction or overtightening,” explains De La Cruz. “You're getting pure torque.”

Although the jackbolts are quick and easy to adjust, one large Superbolt tensioner can house more than a dozen. A single section of just one machine, like the sideframe of a rope shovel, can utilize several tensioners. As a result, while it’s still faster, simpler, and safer than conventional large bolts and tools, loosening and tightening Superbolt connections by hand often requires considerable time and effort.

The Superbolt Tool is a power tool series with integrated drive units and cassettes. Each one is designed to match a specific size of Superbolt tensioner and fit against its jackbolts.

“The Superbolt Tool just comes in and tightens them all at once at the same time, so you don't have to worry about going through and tightening them one by one,” says De La Cruz.

Reducing maintenance time from 40 to 3 hours

The durability and simplicity of Superbolt tensioners make them ideal for mining equipment like rope shovels. Used to dig through and remove soil and rock – as well as to load valuable ore – these enormous machines experience extreme mechanical stress. Rope shovels are critical to operations, so unexpected repairs or prolonged maintenance have serious consequences.

“If a machine like that is down, it’s costing about $60,000 to $80,000 each hour it's not running, and that’s being conservative,” says De La Cruz, who explains that mining operations still using conventional large bolts for their machinery often suffer serious financial loss from the reduced productivity of taking equipment offline. “If they're replacing these nuts and bolts once a year and it's down for two weeks, it can cost up to a million dollars.”

GHT had helped the mine in Carajás save quite a bit when it first installed Superbolt tensioners in the client’s rope shovels. The maintenance time for removing or installing the bolted connections securing one sideframe went from 40 hours to 20 hours. But the Superbolt Tool reduced it even further to just 3 hours per sideframe.

According to Luiz Leite, Machinery and Equipment Supervisor at GHT, everyone involved was pleased with the outcome.

“The client was extremely satisfied with the work completed. I highly recommend the Superbolt Tool product due to its capacity to meet the adjustment deadline and ease of operation,” he says.

There’s obvious satisfaction in avoiding the financial impact of key equipment not being operational. Yet, as De La Cruz points out, the Superbolt Tool has additional cost-saving effects. It requires fewer maintenance workers, for example, who are then free to do other things.

But any gains directly or indirectly attributed to using the Superbolt Tool will always be due to its core benefit. “The number one thing is the reduction of maintenance time,” says De La Cruz. “It just saves so much time.”