Alstom and Nord-Lock Group: A secure coupling

French multinational Alstom is a global player in the rail transport industry. The company has a raft of international customers seeking the most comprehensive range of products and services on the rail market — from trains and integrated systems to signalling and services.

To ensure that Alstom maintains its position as the preferred partner for clients like SNCF and Eurostar, the group looks to a broad range of suppliers to provide the solutions and services it needs. Nord-Lock Group has worked with Alstom since 2014, providing solutions for their tough engineering challenges. Alstom first started using Superbolt technology from Nord-Lock Group almost by chance. “I’m in a rail transportation working group along with representatives from some of the big rail customers like French railway operator SNCF, and manufacturers like Bombardier Transport. Three years ago, we were invited to a two-day workshop at the Nord-Lock Group premises in Lyon, France,” says Luc Moyart, Fasteners Expert and Right First Time Manager at Alstom. “Among the products they showed us was their Superbolt tensioner range, and I thought they might be perfect for a certain type of coupler assembly that we were using on trains for the Los Téquès project for the Caracas subway,” he says.

Alstom first started using Superbolt technology from Nord-Lock Group almost by chance. “I’m in a rail transportation working group along with representatives from some of the big rail customers like French railway operator SNCF, and manufacturers like Bombardier Transport. Three years ago, we were invited to a two-day workshop at the Nord-Lock Group premises in Lyon, France,” says Luc Moyart, Fasteners Expert and Right First Time Manager at Alstom. “Among the products they showed us was their Superbolt tensioner range, and I thought they might be perfect for a certain type of coupler assembly that we were using on trains for the Los Téquès project for the Caracas subway,” he says.

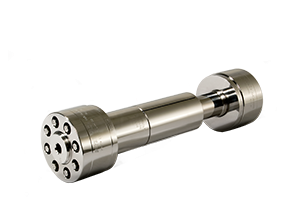

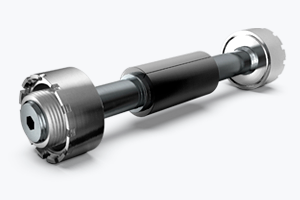

These couplers require very large diameter bolts, which present certain issues when it comes to tightening. Although Alstom hadn’t actually been looking for a solution, the new Nord-Lock Group Superbolt technology they’d seen offered some clear advantages. “I thought they might be suited to train bars and couplers because these require big 30mm bolts that were proving tricky to tighten,” says Moyart.

The perfect solution to secure train couplers

Moyart was right, and since then, Alstom has used Superbolt tensioners for two more projects. After their adoption in 2014, they were used at Alstom’s Lapa site in Brazil and on trains for a South African network. The third project involved trains produced in Katowice, Poland, for the Riyadh subway system in Saudi Arabia.

“Superbolt tensioners limit the torsion in the screws used for fixing the couplers because they use pure tension. The fusible screws are machined and calibrated so that in the event of an impact – a crash for example – they will snap at a certain pressure, leaving the coupler to slip beneath the train, thus avoiding derailment,” Moyart explains. “Superbolt tensioners can also be used in places that are tricky to access, and they aren’t sensitive to the different temperatures we might experience in different locations over the year, unlike with hydraulic tightening solutions,” he adds.

Superbolt tensioners can also be used in places that are tricky to access, and they aren’t sensitive to the different temperatures we might experience in different locations over the year, unlike with hydraulic tightening solutions.

Using Superbolt technology has allowed Alstom to reduce manufacturing time due to coupler installation as well as simplify assembly. “The tensioners are easier to access, which has saved us money in terms of industrial capacity and handling. We need less storage for the tools because we can now tighten these M30 screws with a simple torque wrench, and they don’t require the same hydraulic benches to manage the tightening process like before,” says Moyart.

Furthermore, Alstom has found that Superbolt tensioners are not just integrated into an assembly more easily, but they can be assembled and dismantled with greater ease too. “One major advantage is that Superbolt tensioners can be reused, unlike our previous bolts. which had to be discarded once they were removed from an assembly. Superbolt tensioners have a lifetime guarantee, which represents significant savings,” says Moyart.

Another key benefit is that fewer Alstom employees are suffering from repetitive strain injury and other problems related to bolt tightening since the group started using Superbolt tensioners. “People handling the heavy equipment used for hydraulic tightening are prone to health issues, and our employees have literally felt the benefits of this technology, and they’re very happy about that,” explains Moyart.

Innovating a traditional industry

“The railway industry is a fairly traditional world and employees can sometimes be a little sensitive to change, making it tricky to introduce new ways of doing things, but we’ve had excellent feedback,” says Moyart. “They can see the benefits, not just in terms of their health, but also in terms of the working environment and how these tensioners have made their lives easier. They have been trained by Nord-Lock Group teams to use Superbolt tensioners, and it’s been a very smooth transition,” he adds.

They can see the benefits, not just in terms of their health, but also in terms of the working environment and how these tensioners have made their lives easier.

Naturally, it is important for a group like Alstom to cultivate positive relationships with its suppliers, something that has been very easy to do with Nord-Lock Group. “Our relationship with Nord-Lock Group has always been excellent – we have worked closely with them throughout the experience. When we wanted to carry out initial tests, looking at how Superbolt technology might work, they came to our premises several times to consult with us and offered a lot of support,” explains Moyart. “They also came to train our operators, which was very successful, and since we validated the solution and started using the bolts, we haven’t had a single issue with them,” he says.

Alstom has recently signed a number of new contracts for similar solutions and Moyart is certain they will be working with Nord-Lock Group again. “I wouldn’t be surprised if I visited Nord- Lock Group again to see an innovative new product and subsequently find an application for it in our technology. Indeed, improvement is part of our group culture – that’s what we do!” he concludes.

Alstom and Nord-Lock Group collaboration technical insights

“Alstom switched to Superbolt tensioners on their railway coupler applications to ensure that any potential crash would be ‘smoother’, and the coupler would move back underneath the carriage,” explains Olivier Gaillard, Sales Manager France at Nord-Lock Group. “They wanted to use double-slotted nuts but the existing fuse bolts risked breakage during tightening. Regular hydraulic tools brought too much torsion, which is why they looked to Nord-Lock Group Superbolt tensioners that tighten using pure tension,” he says.

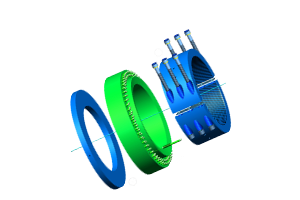

“The French railway market tends to be rather conservative and introducing new technology can be challenging, so we worked with the engineering methods and industrialization departments at Alstom, along with individual operators, to set up a first design win of 1,100 nuts,” says Gaillard. The second step was to undertake a design-to-cost action on a large scale, resulting in a new project encompassing 57,600 nuts. “Since 2014, 1,700 M30 nuts have been delivered. We are looking forward to new opportunities both with Alstom and other rolling stock manufacturers,” he concludes.

Client: Alstom Transport

End customers: Compañia Anónima Metro de Caracas, Venezuela for the Los Teques project

Metrorail, South Africa for the Prasa project

Riyadh Metro, Saudi Arabia for The Riyadh project

Application: Bars and couplers for mass transportation trains

Nord-Lock Group solution: Superbolt tensioners

Benefits gained: Reduced costs and improved operator experience