World Class Manufacturing

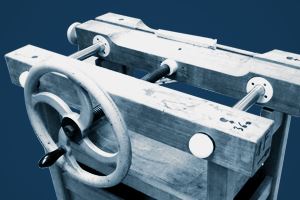

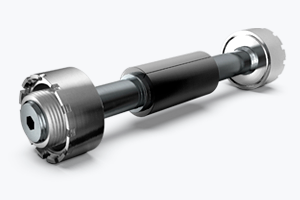

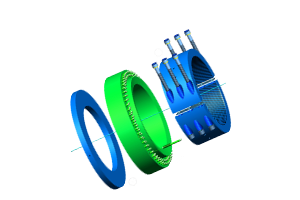

The Nord-Lock Group and it’s Superbolt manufacturing facilities have invested heavily in world class CNC machining operations. Our capacity for machining allows quick turnaround of standard and special multi-jackbolt tensioners and other related bolting products.

Most standard products are available off the shelf or in a short lead time. In addition, the engineering, manufacturing and production personnel have accumulated decades of knowledge and training in producing some of the finest threaded components and products in the world.

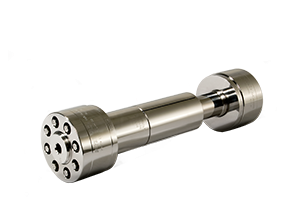

Quality & Traceability

Special attention has been paid over the years to developing and implementing our quality systems to work on highly critical and demanding industries. Quality control, including thread gauging and measurement systems, is standard operating procedure. Multi-jackbolt tensioner nut and bolt bodies are marked for full traceability.

| Example of part marking information | |

| SUPERBOLT | |

| Part number: | MT-M36x4 |

| Lot number: | 7900 |

| max. Load | 457kN |

| Material code: | CrM |

Note: Information may vary. Custom markings possible upon request.