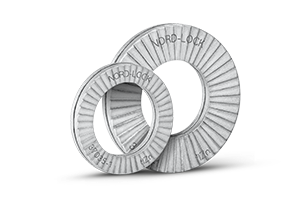

| Application parameter | ||||

| Steel | Stainless steel (ss) |

254 SMO® | ALLOY C-276 |

ALLOY 718 |

| Steel type | ||||

| EN 1.7182 | EN 1.4404 | EN 1.4547 | EN 2.4819 or equivalent | EN 2.4668 or equivalent |

| Examples of applications | ||||

| General steel applications | General stainless steel applications. Non chlorine / acid environments | General salt water applications, pumps, chloride applications, heat exchangers, nuclear, desalination, food processing & medical equipment | General acidic environments, process and chemical industry, evaporators, offshore downhole tooling | Applications with high temperatures, gas turbines, turbo charges, incinerators |

| Available for bolt sizes | ||||

|

M3-M130 #5 to 5" |

M3-M80 #5 to 3 1/8" |

M3-M39 #5 to 1 1/2" |

M3-M39 available on request #5 to 1 1/2" available on request |

M3-M39 available on request #5 to 1 1/2" available on request |

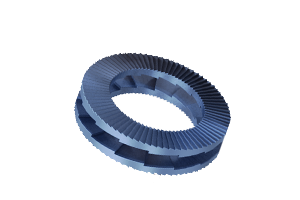

| Washer types | ||||

|

Regular outer diameter (NL3 - NL130) Enlarged outer diameter (NL3,5sp - NL36sp) |

Regular outer diameter (NL3ss-NL80ss) Enlarged outer diameter (NL3,5spss - NL30spss) |

Regular outer diameter (NL3ss-254 - NL39ss-254) Enlarged outer diameter (NL3,5spss-254 - NL27spss-254) |

Regular outer diameter (NL3ss-276 - NL39ss-276) Enlarged outer diameter (NL3,5spss-276 - NL27spss-276) |

Regular outer diameter (NL3ss-718 - NL39ss-718) Enlarged outer diameter (NL3,5spss-718 - NL27spss-718) |

| Treatment surface coating | ||||

| Through hardened Delta Protekt® base coat (KL100) and top coat (VH302GZ) | Surface hardened | Surface hardened | Surface hardened | Surface hardened |

| Washer hardness* | ||||

| ≥ 465HV1 | ≥ 520HV0,05 | ≥ 600HV0,05 | ≥ 520HV0,05 | ≥ 620HV0,05 |

| Corrosion resistance | ||||

| Minimum 1,000 hours in salt spray test (according to IS09227) | PREN 27** | PREN 45** | PREN 68** | PREN 29** |

| Bolt grades | ||||

| Up to 12.9 | Up to A4-80 | |||

| Temperature range*** | ||||

| -50°C to 200°C | -160°C to 500°C | -160°C to 500°C | -160°C to 500°C | -160°C to 700°C |

* In order to assure the unique mechanical locking function of the Nord-Lock washers, the hardness of the mating surfaces must be lower than the hardness of the Nord-Lock washers.

** PREN (Pitting Resistance Equivalent Number) = %Cr + 3,3x%Mo + 16x%N. Figures in table valid for base material.

*** Temperature recommendations based on information from the raw material supplier and from tests. Locking function not affected within the specification.