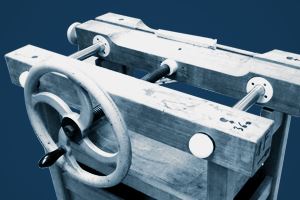

Joint Guide

|

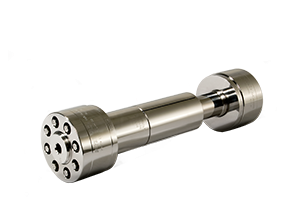

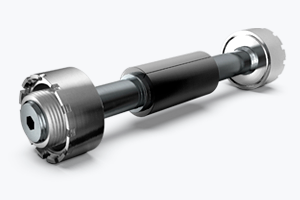

Stud bolts |

|

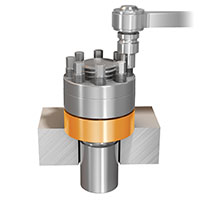

Through-holes |

|

Tapped holes |

|

Counterbores |

Installation Tips

Importation considerations when applying Superbolt tensioners for various field application scenarios.

|

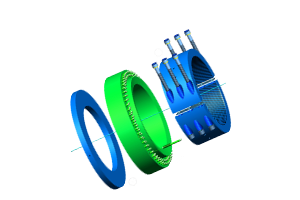

Centering of washer on thread |

|

Material with low strength |

|

Large or slotted holes |

|

Space requirements |

|

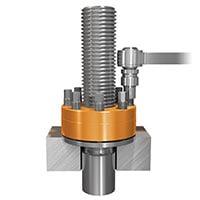

Tensioner at the end of stud |

|

Very long through-stud |