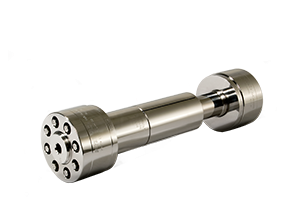

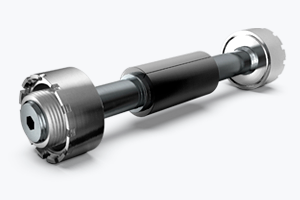

Unlike traditional hydraulically actuated coupling bolts, Superbolt HyFit:

- Uses two separate dimensionally different heads and just one operating pressure, eliminating the risk of using the wrong pressure during operation.

- Uses heads that have a unique design so there is no way to use them incorrectly during the procedure.

- Has a new HyFit nut which is used to tension the bolt, so it can be retrofitted to any existing coupling bolt and used with the HyFit system.

Superbolt HyFit is ideal for steam turbines, gas turbines, marine propulsion drives, and all heavy rotating equipment providing benefits which include;

- SECURE - Elimination of internally connected thread puller.

- EFFICIENT - Design that removes the need for oil injection removal methods, preventing a known mode of failure.

- COST SAVING - Hole preparation costs are reduced as less demanding hole tolerances are required.

- SAFE - Use of two-dimensionally different hydraulic heads with one operating pressure.

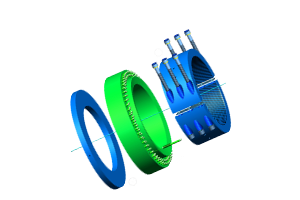

- ACCURATE - Radial fit which allows for better coupling alignment and concentricity.

- COST-EFFICIENT - Fully reusable, only requires sleeve replacement for rotor changes.

- PRACTICAL - Superbolt HyFit split sleeves allow greater expansion to achieve hole tolerances more easily.