Why Lug Wear is an Unrealized Problem on Refuse Trucks

Lug wear is one of the biggest causes of maintenance on refuse trucks, costing operators thousands in downtime. Despite the inconvenience, this wear is often accepted as unavoidable. This means that traditional lug wear solutions continue to dominate the waste sector, even though these are costly and time consuming.

Lug wear is caused by the wear to lug holes located on cylinder rod ends and between moving mechanical parts. Lug holes contain pivot pins, which provide applications with the flexibility they need to operate efficiently. However, traditional straight pins accentuate lug wear. This is due to the gap that must exist between the pivot pin and the lug holes of the machine during installation. This gap wears down the lug holes when the machine is exposed to heavy loads and vibration.

Furthermore, when a pin is loaded onto the lugs, all the pressure is forced onto a small area of the lug holes, deforming the area permanently. Lugs are also typically made from softer materials than the pin, and easily lose their shape after repeatedly coming into contact with a hard pin during operation.

Consequences for refuse trucks

Refuse trucks are some of the most susceptible vehicles when it comes to lug wear. This is because they are designed with pivot locations that allow them to lift garbage into the truck using a special arm. Since refuse trucks lift hundreds of heavy loads each day, this puts pressure on the lug holes, which become worn over time and require maintenance.

The most popular form of maintenance to repair worn lugs when traditional pivot pins are used is welding in lug replacements. This process can take multiple days and during this time the vehicle is completely inoperable – increasing the cost of downtime. This process also necessitates experienced mechanics with specialized equipment, skyrocketing the cost of labor and materials.

Although these factors all contribute to high maintenance costs for the owner, the most problematic issue with this solution is that it is not permanent. Lug wear typically requires repairing three to four times during a refuse vehicle’s lifetime or every 3,000 to 4,000 hours. Each time lug wear reoccurs, operators are forced to repeat the same time-consuming and inefficient maintenance routine.

A permanent solution for the waste industry

Although lug wear maintenance is viewed as an inevitable part of operating a fleet of refuse trucks, this does not have to be the case. In fact, the high cost of downtime and labor can be avoided entirely when opting for alternative technologies.

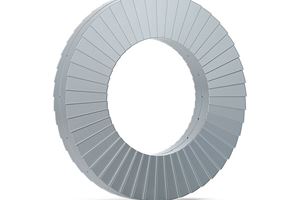

Expander System permanently prevents lug wear and eliminates the need for future lug repairs. Since an Expander System pivot pin can be mounted directly into worn lugs, it does not have to be taken in for repair. The simplicity of the system means that anyone on site can install it and operations can resume after a couple of hours – an effective solution to increase the efficiency of refuse trucks.