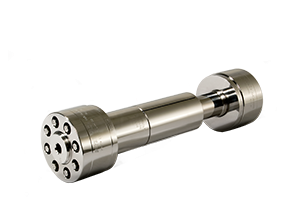

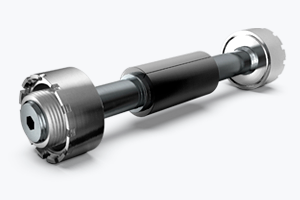

Standard Range

EzFit mechanical expansion bolts can be designed using latest FEA technology for any type of coupling with bolts of diameter 20mm (3/4″) or upwards.

Unique features and advantages of both hydraulic and mechanical expansion sleeve coupling bolts can be combined to best suit your specific requirements.

|

A Type

|

|

B Type

|

|

C Type

|